Two Essential Log Splitter Modifications Every Owner Should Consider

- February 19, 2024

- 7 comment

When it comes to splitting wood, the primary concerns are always efficiency and safety. Even though there’s a wide variety of log splitters on the market, adding specific upgrades can greatly enhance their performance.

This article focuses on two crucial modifications that are designed to increase the productivity of your log splitting tasks while also providing additional safety measures.

These enhancements are not just minor improvements; they address fundamental aspects of the log splitting process to make it faster, safer, and more efficient. By implementing these changes, users can significantly benefit from a more streamlined operation that maximizes the potential of their equipment.

List of Two Essential Log Splitter Modifications:

Maximize Your Log Splitting Efficiency with These Critical Upgrades

Turning logs into firewood can be an arduous task, demanding not just strength and stamina, but also a keen eye for technique and safety. Yet, the efficiency and ease of this process can be significantly improved with a couple of crucial modifications to your log splitter. While many users are satisfied with their equipment’s factory settings, they often overlook the transformative potential of these upgrades.

These enhancements not only boost the machine’s performance but also reduce physical strain and increase safety for the user. Here’s a detailed walkthrough on how to implement these vital modifications to your log splitter, ensuring you get the most out of every split:

- Install a Log Splitter Table: A common challenge when splitting wood is managing the split logs, especially if you’re working alone. They can scatter, requiring you to bend down repeatedly to pick them up, which is time-consuming and bad for your back. By attaching a custom or commercially available log splitter table, you create a space where split logs can fall and stay within easy reach. This modification saves time and reduces physical strain, allowing for a more efficient workflow.

- Enhance with a 4-Way Splitting Wedge: Most log splitters come equipped with a standard single wedge, designed to split logs into two pieces. By upgrading to a 4-way wedge, you can quadruple your productivity, splitting logs into four pieces in a single pass. This upgrade is particularly useful for preparing firewood, as it significantly reduces the number of passes required to reach your desired log size. Installing a 4-way wedge is straightforward and can drastically cut down your splitting time.

Implementing these modifications to your log splitter can revolutionize your wood-splitting experience, making the process faster, safer, and more enjoyable. Whether you’re preparing firewood for the winter or managing fallen trees on your property, these essential upgrades will ensure your log splitter is working as efficiently as possible.

1. Log Catching Rack

One of the most practical modifications you can make to a log splitter is the addition of a log catching rack. This feature addresses a common issue faced by many: managing split logs. A log catching rack is essentially a shelf attached to the side of the log splitter, designed to hold logs once they’ve been split. This modification proves invaluable for several reasons:

- Efficiency in Handling: When dealing with larger rounds, you can split one half while the other rests on the rack, ready for the next split. This eliminates the need to constantly bend down to pick up split logs from the ground, saving time and reducing physical strain.

- Facilitates Teamwork: For operations involving two people, the rack allows one person to preload logs onto it. This ensures a seamless supply of logs to the splitter, maintaining a steady workflow without pauses.

- Protects the Engine: Extending the rack over the engine serves a dual purpose. Not only does it act as an engine guard, protecting vital components like the plastic air cleaner and gas cap from falling logs, but it also provides a convenient platform for refueling. This thoughtful addition safeguards the engine while enhancing user convenience.

2. Stroke Limiter

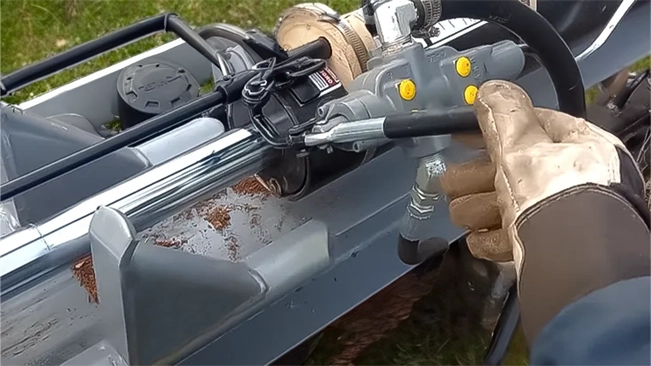

The second modification, a stroke limiter, is a game-changer for those who frequently split logs shorter than the maximum capacity of their log splitter. Standard log splitters are often designed to accommodate logs up to 26 inches in length. However, if you primarily split logs around 15 to 16 inches, a significant portion of the cycle time is wasted waiting for the ram to return.

A stroke limiter is a simple yet ingenious device that allows you to customize the return stroke of the splitter’s ram. Here’s how it works:

- Cocked and Loaded Mechanism: When set in the reverse position, the limiter is ready. As the ram retracts and hits a predetermined point, it activates a pin that stops and disengages the handle, preventing the ram from retracting further than necessary.

- Customizable Stroke Length: By drilling holes in the rod at various intervals, you can adjust the length of the stroke to match the size of the logs you’re splitting. This ensures that the ram stops just beyond the point where you would manually intervene, saving time and reducing the wear on the machine.

These two modifications — a log catching rack and a stroke limiter — are not just add-ons but essential upgrades that enhance the efficiency, safety, and longevity of your log splitter. By implementing these changes, you can transform your log splitting experience, making it smoother, faster, and more enjoyable.

Pros and Cons

Pros

- Quadruples efficiency per log pass

- Reduces wear and tear on the machine by minimizing the number of cycles

- Saves on fuel consumption

Cons

- Not suitable for all log types, especially those with lots of knots

- Can require more power from the splitter, not ideal for lower-powered models

Integrating the Modifications

Implementing these modifications requires a blend of mechanical aptitude and adherence to safety standards. While some may opt for DIY approaches, consulting with professionals or seeking out pre-made solutions is advisable to ensure that the modifications do not compromise the log splitter’s integrity or safety.

Final Thoughts

The log catching rack and stroke limiter are essential modifications that significantly enhance the functionality, efficiency, and safety of log splitters. By addressing common challenges faced during the splitting process, these modifications offer practical solutions that can greatly benefit anyone looking to optimize their firewood production. Whether for personal use or commercial operations, integrating these enhancements into a log splitter setup promises a smoother, more efficient, and safer wood splitting experience.

Frequently Asked Questions

- What are the two essential modifications for a log splitter?

The two essential modifications include adding a log catching rack to hold split logs and installing a stroke limiter to adjust the ram’s return distance for efficiency. - How does a log catching rack improve log splitting operations?

A log catching rack significantly improves efficiency by catching and holding split logs, reducing the need to bend down and pick up logs from the ground. It also facilitates a smoother workflow, especially when working with a partner. - Can the log catching rack be installed on any log splitter?

Yes, with some basic tools and materials, a log catching rack can be adapted and installed on most log splitters. The design might need to be customized based on the specific model and size of your log splitter. - What is the purpose of a stroke limiter on a log splitter?

A stroke limiter allows you to adjust the return distance of the log splitter’s ram, reducing the cycle time for splitting shorter logs and enhancing overall efficiency. - How do you adjust the stroke length with a stroke limiter?

The stroke limiter typically involves a mechanism with an adjustable pin or stopper. By positioning this pin, you can control the maximum retraction of the ram, customizing it to the length of logs you typically split. - Are these modifications safe to implement?

Yes, when designed and installed correctly, both the log catching rack and the stroke limiter are safe and can even enhance the overall safety of your log splitting operations by reducing manual handling and optimizing the machine’s use. - Do I need specialized tools to make these modifications?

Basic hand tools, such as a drill, wrenches, and possibly a welder (for metal work), are generally sufficient to install these modifications. The exact tools required may vary depending on the design and materials you choose. - Will modifying my log splitter void its warranty?

It’s possible that modifications could affect your warranty. It’s best to check with your manufacturer or consult your warranty documentation before making any modifications. - How can I ensure the modifications fit my specific log splitter model?

You may need to take measurements and possibly create a custom design to ensure the modifications fit your log splitter model. Consider consulting with a professional or someone experienced in DIY projects if you’re unsure. - Where can I find resources or guides to help me make these modifications?

Online forums, DIY websites, and videos on platforms like YouTube can be excellent resources for ideas and step-by-step guides. Additionally, you might find specific instructions or kits available for purchase from log splitter accessory manufacturers.

We’re eager to hear from you! Share your personal experiences and thoughts about implementing the two essential log splitter modifications discussed here in the comments section below. Whether you’ve added a log catching rack, installed a stroke limiter, or both, your insights could greatly benefit fellow wood splitters looking to enhance their efficiency and safety. Your feedback is invaluable in helping others make informed decisions about these game-changing upgrades!

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

7 comments

I've seen a vertical splitter where you must use both hands to control the ram rather than none. It completely eliminates the risk of accidental harm to arm or hand.

Boyd Cassie

February 22, 2024 9:17 pmCan the wedge head on my 25ton Champion Log Splitter be changed to a 4 way splitting wedge ?

Patrick

February 22, 2024 1:50 pmAbsolutely, you can switch to a 4-way wedge for your 25-ton Champion Log Splitter if it fits. Always good to double-check compatibility! Also, take a look at our post on the Best log splitters for the money for more great tips and recommendations. It could be really helpful!

Edward Smith

February 26, 2024 6:36 amOne modification I've always wanted to do is a foot switch for ram control, freeing up both hands so you could control the logs better using 2 hands

James wirsbinske

February 21, 2024 3:22 pmI made my own splitter with a built in table about twenty years ago. Has built in stroke control. Hands free automatic ram return and splitting.

By my math - a 4 way wedge will double your output. A single wedge splits your round into 2 pieces, a 4 way wedge splits your round into 4 pieces. That DOUBLES your output, not quadruple. If I am am wrong, I'm listening.

Barry Emslie

February 23, 2024 12:46 amHi Barry, You are right. A single wedge splits a round into 2 pieces. On the other hand, a 4-way wedge splits a round into 4 pieces. So, indeed, the 4-way wedge doubles your output compared to the single wedge. Thanks for keeping the math sharp! If you’re considering a log splitter, check out our article on Best log splitter for the money.

Edward Smith

February 26, 2024 6:57 am