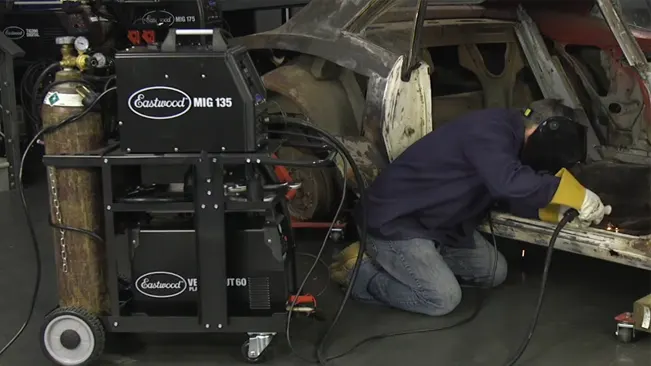

Eastwood Welding Cart Review

- March 20, 2024

- 0 comment

To craft a detailed review of the Eastwood Welding Cart, let’s delve into several key aspects that are crucial for anyone considering this product. This comprehensive overview will cover the cart’s design and construction, capacity, mobility, additional features, and overall value for money, providing a well-rounded insight into its performance and suitability for various welding needs.

We’ve got your welding covered! Find comfy, Best welding gloves, Best welding carts, plus top picks for Best TIG Welder, Best MIG Welder & Best ARC Welders – all without breaking the bank!

Eastwood Welding Cart Specifications

- Material: Heavy-duty steel.

- Features: Sloped shelf, multi-level storage, cable hangers, cylinder rack with chain.

- Mobility: 4 casters (2 fixed, 2 swivel), lockable front wheels.

- Space Efficient: Compact, adaptable design.

- Compatibility: Suits a variety of welders/plasma cutters.

Design and Construction

The Eastwood Welding Cart is designed with functionality and durability in mind. Typically constructed from heavy-duty steel, these carts are built to withstand the rigors of a welding workshop or garage environment.

The robust construction ensures that it can carry substantial weight, usually accommodating most types of welding machines and gas cylinders. The design often includes a sloped top shelf for easier access to the welder controls, and a series of shelves and hooks to organize welding accessories efficiently.

Capacity

A critical feature of any welding cart is its capacity to hold welding equipment securely. The Eastwood Welding Cart shines in this aspect, offering a generous loading capacity that can easily support a welder, a sizable gas bottle, and various welding accessories such as helmets, gloves, and consumables.

The thoughtful layout of the shelves and hooks maximizes storage space without compromising the cart’s footprint, making it an excellent choice for both small workshops and larger industrial settings.

Cable Wrap Hangers

The Eastwood Welding Cart incorporates thoughtfully designed Cable Wrap Hangers, a feature that significantly enhances the organization and efficiency of any welding workspace. These integrated hangers or hooks are specifically engineered to provide a dedicated space for the neat storage of welding cables.

This design consideration not only prevents the cables from tangling, which can be a common and frustrating issue in the welding process, but also minimizes the risk of damage to the cables. Keeping welding cables organized and easily accessible not only streamlines the workflow but also contributes to a safer working environment by reducing trip hazards and potential electrical issues. This attention to detail in the design of the Eastwood Welding Cart showcases an understanding of the practical needs of welders, emphasizing convenience, safety, and the longevity of equipment.

Mobility

The mobility offered by the Eastwood Welding Cart is a standout feature that significantly enhances the functionality and user experience in any welding setup. With its heavy-duty casters, this cart is engineered to provide smooth and effortless movement across a variety of workshop floor conditions, whether it’s over smooth concrete or less forgiving surfaces.

The cart’s design incorporates a strategic mix of two fixed and two swivel casters, striking an optimal balance between stability and maneuverability. This allows users to easily reposition the cart as needed during different phases of a project, ensuring that welding equipment is always within reach. The swivel casters make navigating tight spaces and corners a breeze, while the fixed casters offer the necessary resistance to keep the cart securely in place when stationary. This mobility feature not only improves workflow efficiency by reducing the need to carry heavy equipment but also enhances safety by minimizing the risk of strain injuries and equipment damage. The thoughtful integration of these mobility solutions underscores the Eastwood Welding Cart’s design philosophy, prioritizing ease of use, flexibility, and the overall satisfaction of the welding professional.

Additional Features

Eastwood often incorporates several additional features into their welding carts to enhance convenience and efficiency. For instance, a cable wrap hanger is a common inclusion, enabling users to keep welding cables neatly organized and tangle-free. Some models may also feature a built-in cylinder rack with a safety chain, securing the gas cylinder in place during movement. These thoughtful touches reflect Eastwood’s understanding of welders’ needs and challenges.

Pros and Cons

Pros

- Made from heavy-duty steel, ensuring long-term use and stability.

- Features like the sloped shelf, cable hangers, and multiple storage levels help keep your welding equipment and accessories neatly organized.

- Equipped with four casters, including two that swivel and lockable front wheels, making it easy to move around while offering Compact enough to fit in tight spaces, yet provides ample storage for essential welding tools and a gas cylinder.

- Designed to accommodate a wide range of welding machines and plasma cutters.

Cons

- Like many welding carts, assembly is needed, which might be a drawback for those who prefer ready-to-use products.

- While it’s great for organizing small to medium-sized welding accessories, storage space might be limited for larger tools.

- Depending on the budget, some may find the cost a bit high compared to simpler, less robust options on the market.

Maintenance of Eastwood Welding Cart

- Regular Cleaning

Wipe down the cart regularly with a clean, dry cloth to remove dust and debris. For tougher grime, use a mild detergent diluted in water and ensure the cart is dry afterwards. - Rust Prevention

Check for any signs of rust or corrosion, especially if the cart is used in a humid environment or stored outdoors. Treat any rust spots immediately with rust remover and apply a protective coating if necessary. - Caster Maintenance

Inspect the casters periodically for wear and tear. Lubricate the swivel bearings and wheel axles with a light machine oil to ensure smooth movement. - Safety Chain Inspection

Examine the safety chain on the cylinder rack for any signs of wear or damage. Replace the chain if it shows any sign of weakness or wear to ensure gas cylinders are securely fastened. - Bolt and Screw Tightening

Periodically check all bolts and screws for tightness. Vibrations from moving the cart and normal use can loosen fasteners over time, so re-tighten them as needed. - Shelf Alignment Check

Ensure that all shelves and storage compartments are properly aligned and securely attached. Adjust or tighten any components that appear to be misaligned. - Cable Hanger Check

Inspect cable hangers for any damage or deformation. Replace if necessary to prevent any potential cable damage. - Weight Distribution

Regularly check that the weight on the cart is evenly distributed to avoid tipping. Avoid overloading the top shelf to maintain stability. - Avoid Excessive Exposure to Moisture

If the cart is used in a damp environment, make sure to dry it off at the end of the day to prevent rust and corrosion. - Storage Location

When not in use, store the cart in a dry, covered area to protect it from the elements and reduce the risk of rusting and corrosion.

About this Eastwood Welding Cart

Heavy-Duty Steel Construction

Crafted with high-quality steel to withstand the intense demands of welding tasks, offering exceptional durability and a solid foundation for welding machines and heavy gas cylinders.

Sloped Top Shelf

Ingeniously designed for ergonomic access to welder controls, minimizing strain and enhancing user comfort during operation. The slope ensures visibility and ease of adjustment without the need to bend or stretch.

Multiple Storage Shelves and Hooks

Strategically placed shelves and hooks provide organized storage for a wide array of welding accessories, including helmets, gloves, and consumables. This design promotes efficiency by keeping essential tools orderly and readily available.

Cable Wrap Hangers

Specifically designed hangers or hooks for wrapping and securing welding cables, significantly reducing the risk of tangling and wear. This feature helps maintain a clutter-free workspace and extends the lifespan of cables.

Built-In Cylinder Rack with Safety Chain

A dedicated space for securely holding gas cylinders, equipped with a safety chain to prevent movement or tipping. This safety feature is crucial for maintaining stability and preventing accidents in the workspace.

Value for Money

Considering the quality of materials, construction, and the thoughtful design features, the Eastwood Welding Cart offers excellent value for money. It is priced competitively, making it accessible to hobbyists and professionals alike. The durability of the cart means it’s a long-term investment that will serve well over many years, further enhancing its value proposition.

Conclusion

The Eastwood Welding Cart is a standout option for anyone in need of a reliable, well-designed, and user-friendly solution for organizing and mobilizing their welding equipment. With its sturdy construction, ample storage capacity, ease of mobility, and thoughtful additional features, it meets the needs of a wide range of welding tasks. Whether you’re a professional welder or a weekend warrior in the garage, this cart is likely to exceed your expectations, offering a blend of performance and value that’s hard to beat.

FAQs

- What are the dimensions of the Eastwood Welding Cart?

Details the size and space requirements of the cart to help potential buyers assess if it fits their workspace. - Can the Eastwood Welding Cart accommodate all types of welders and plasma cutters?

Addresses compatibility concerns with different welding machines and equipment. - How much weight can the Eastwood Welding Cart support?

Provides information on the maximum load capacity, ensuring users can safely store their equipment. - Are the cable wrap hangers large enough for all types of cables?

Clarifies the size and capacity of the cable hangers to manage expectations about cable organization. - Is assembly required for the Eastwood Welding Cart, and how difficult is it?

Offers insights into the assembly process, including time commitment and complexity. - How do I lock the swivel casters on the Eastwood Welding Cart?

Gives instructions or tips for effectively using the locking mechanism on the casters to ensure stability during use. - Can the Eastwood Welding Cart be used outdoors?

Discusses the cart’s durability and suitability for outdoor use or in different environments. - What materials is the Eastwood Welding Cart made from?

Provides details on the construction materials to assure users of its quality and durability. - Are there any accessories available for the Eastwood Welding Cart to enhance its functionality?

Informs users about available add-ons or accessories that can be purchased to customize or improve the cart’s utility. - How do I maintain and clean the Eastwood Welding Cart?

Offers maintenance tips and cleaning recommendations to keep the cart in optimal condition over time.

We’re eager to hear from you! Share your personal experiences and insights about the Eastwood Welding Cart in the comments section below. Whether it’s about its durability, mobility, or how it’s improved your welding projects, your feedback could help others in our community make informed decisions. Let’s help each other build better workspaces!

Jack Williams

Forestry AuthorI'm Jack Williams, Jack Williams, my expertise in welding and generator technologies extends beyond traditional boundaries. With over 13 years of experience, I have honed my skills in a range of heavy-duty equipment, focusing particularly on welding and power generation. My passion for nature and commitment to ecological sustainability inform my approach to work. I emphasize safety, efficiency, and staying current with technological advancements. Beyond my technical skills, I am dedicated to sharing knowledge and fostering environmental awareness, aiming to contribute positively to both the welding and generator operation industries.

Leave your comment