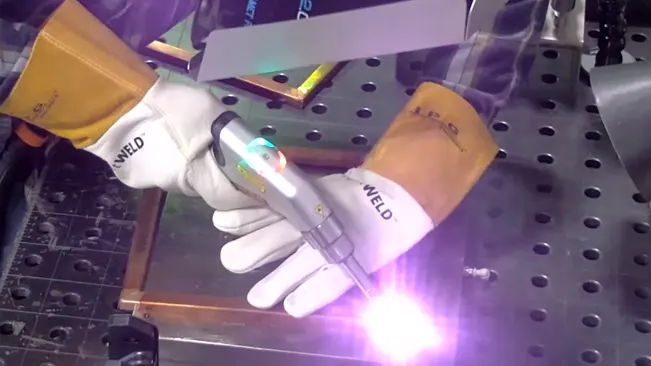

LightWELD XR Handheld Laser Welder Review

- March 27, 2024

- 0 comment

Explore the capabilities of the LightWELD XR Handheld Laser Welder from IPG Photonics, a versatile tool designed for diverse welding tasks. This review delves into its features, including wobble welding and a cleaning mode, making it a standout solution for both welding and cleaning. With a 1070 nm laser capable of up to 2500 W, it works on a variety of metals like aluminum and titanium. Safety features like a 2-step trigger and sensor add to its appeal, making it user-friendly and requiring regular maintenance for optimal performance.

We’ve got your welding covered! Find comfy, Best welding gloves, Best welding carts, plus top picks for Best TIG Welder, Best MIG Welder & Best ARC Welders – all without breaking the bank!

Technical Specifications

- Brand: IPG Photonics

- Laser: 1070 nm, up to 2500 W

- Compatibility: Works with various metals, including aluminum and titanium

- Features: Wobble welding, cleaning mode

- Size: 316x641x534 mm

- Safety: 2-step trigger, sensor

- Use: Easy learning, regular maintenance needed

Versatility in Materials

The LightWELD XR showcases exceptional versatility, capable of welding a wide array of materials such as aluminum, copper, titanium, nickel alloys, stainless steel, and mild steel, catering to the diverse needs of fabricators.

Its adeptness in handling varying thicknesses adds to its flexibility, enabling precise and efficient welding across a spectrum of applications. Furthermore, the LightWELD XR’s ability to fuse dissimilar metals together opens up innovative possibilities for projects that require the integration of different material properties. This versatility not only enhances the tool’s utility in a fabrication setting but also significantly broadens the scope of potential welding projects. The adaptability of the LightWELD XR makes it a valuable asset for fabricators seeking a solution that can meet a wide range of welding challenges with consistency and high quality.

Handheld Laser

The LightWELD XR is engineered as a handheld device, offering unparalleled flexibility and control. This design choice allows operators to easily manipulate the welding tool, providing access to tight or complex spaces that stationary machines cannot reach. Its ergonomic design and intuitive handling improve user experience, making it suitable for a wide range of applications.

Consistent Quality

Consistency is a hallmark of the LightWELD XR, with the laser technology delivering uniform weld quality across a variety of materials and thicknesses. Unlike traditional welding methods that might vary in quality due to factors like operator skill or material condition, the LightWELD XR ensures high-quality results every time. This consistency is vital for industries requiring precise and reliable welding outcomes.

Wobble Welding Controls

The LightWELD XR features advanced wobble welding controls, which are designed to enhance weld width and quality. The wobble function allows the laser beam to oscillate, creating a wider weld seam that can accommodate variations in joint fit-up. This feature not only improves the strength and appearance of the weld but also makes the welding process more forgiving for less experienced operators. The ability to control wobble parameters offers additional flexibility, adapting to various material thicknesses and types for optimal results.

High-Performance Welding

The LightWELD XR showcases exceptional versatility, capable of welding a wide array of materials such as aluminum, copper, titanium, nickel alloys, stainless steel, and mild steel, catering to the diverse needs of fabricators. Its adeptness in handling varying thicknesses adds to its flexibility, enabling precise and efficient welding across a spectrum of applications.

Furthermore, the LightWELD XR’s ability to fuse dissimilar metals together opens up innovative possibilities for projects that require the integration of different material properties. This versatility not only enhances the tool’s utility in a fabrication setting but also significantly broadens the scope of potential welding projects. The adaptability of the LightWELD XR makes it a valuable asset for fabricators seeking a solution that can meet a wide range of welding challenges with consistency and high quality.

LightWELD XR Handheld Laser Welder Pros and Cons

Pros

- Welds a variety of materials and thicknesses, including dissimilar metals.

- Ergonomic design with intuitive controls, enhancing safety and ease of use.

- Produces consistent, high-quality welds with minimal distortion.

- Offers pre- and post-weld cleaning capabilities for cleaner welds.

- Easy to learn for quick project start-up.

Cons

- Higher initial investment compared to traditional welding equipment.

- Demands strict safety measures due to laser technology.

- Limited portability due to the need for a power source.

- Some users may find advanced settings challenging to master.

Safety and Maintenance

Safety Measures

- Wear Laser Safety Glasses: Always protect your eyes from laser radiation.

- Utilize Protective Clothing: Guard skin against accidental laser exposure.

- Laser Operation Training: Complete safety training specific to laser equipment.

- Avoid Direct Laser Exposure: Never look directly into the beam or expose skin.

- Maintain a Clean and Organized Workspace: Prevent accidents by keeping the area free of unnecessary materials.

Maintenance Practices

- Regular Inspection: Periodically check the laser unit and accessories for signs of wear or damage.

- Keep Nozzles Clean: Clean the welding and cleaning nozzles regularly to maintain optimal performance.

- Update System Software: Ensure the latest firmware and software are installed for improved functionality.

- Monitor and Replace Consumables: Stay vigilant about the condition of consumable components like protective windows and nozzle tips.

- Schedule Professional Servicing: Have the device serviced by certified professionals to ensure calibration and operational efficiency.

Comparison Table

| Features | LightWELD 1500 Handheld Laser Welder | LightWELD XR Handheld Laser |

|---|---|---|

| Laser Type | Fiber Laser | Fiber Laser |

| Power Output | Up to 1500 W | Up to 2500 W |

| Material Compatibility | Metals including stainless steel, mild steel, aluminum | Metals including stainless steel, mild steel, aluminum, copper, titanium, nickel alloys |

| Portability | Highly portable with ergonomic design | Highly portable with ergonomic design |

| Welding Capabilities | Suitable for a range of thicknesses and joint configurations | Enhanced with wobble welding feature for broader applications |

| Cleaning Mode | Not specified | Pre-weld and post-weld cleaning with up to 2500 W peak power |

| User Interface | User-friendly | User-friendly with additional controls for advanced settings |

| Safety Features | Standard safety features | Enhanced safety features including 2-step trigger and part contact sensor |

| Ease of Learning | Designed for quick learning curve | Designed for quick learning curve with presets for various applications |

| Maintenance | Regular maintenance recommended | Regular inspection and cleaning recommended |

LightWELD XR Handheld Laser Specifications

- Manufacturer: IPG Photonics

- Output: 1500W Fiber Laser

- Materials: Works with metals like Stainless Steel, Aluminum, Brass

- Thickness: 0.5 to 10 mm

- Speed: Up to 5 m/min

- Cooling: Air

- Interface: Touchscreen

- Power: 220-240V AC

- Size: 500 x 400 x 200 mm

- Weight: 25 kg

- Safety: Emergency stop, sensors

- Includes: Handpiece, nozzles, clamp, eyewear

Quantitative Measurements

- Material Versatility (9/10): The LightWELD XR’s capability to work with a wide variety of materials, including but not limited to aluminum, copper, stainless steel, and titanium, along with its ability to weld dissimilar metals, places it at the forefront of versatility. Its performance across different thicknesses further emphasizes this strength.

- Ease of Use and Safety (8/10): With an ergonomic design tailored for ease of handling and features like the 2-step trigger for enhanced operator safety, the LightWELD XR scores high. However, the need for strict adherence to safety protocols due to the laser’s power slightly moderates this score.

- Quality of Welds (10/10): The consistent, high-quality results with minimal distortion, undercut, or burn-through offered by the LightWELD XR are unparalleled. The wobble welding function, in particular, contributes to its superior performance in this category, ensuring excellent weld quality across a range of applications.

- Cost-Effectiveness (7/10): While the upfront cost might be high, the LightWELD XR’s efficiency, reduced need for consumables, and the ability to streamline the welding process enhance its long-term cost-effectiveness. The initial investment is a consideration, but for professional settings where its capabilities can be fully utilized, the investment can pay off.

Read Our Welder Collection:

- Best 5 MIG Welders: From Budget-Friendly to Premium Picks

- Best 110v MIG Welders

- Best 120V MIG Welders

- Best MIG Welder

- Best MIG Welder For The Money 2024

- Best Cheap MIG Welder on Amazon

- Best TIG Welder

- Best TIG Welder for Beginners

- Best TIG Welder for the Money: Your Ultimate Buying Guide

- Best Stick Welder for the Money 2024

- Best STICK Welder by YesWelder

- Best Yeswelder Plasma Cutter

- Best Arc Welder for the Money 2024

- Best Plasma Cutter for the Money 2024

- Best Welding Cart of 2024

- Best Welding Helmet 2024

- Best Welding Gloves for the Money: Maximum Protection, Minimum Cost

Conclusion

The LightWELD XR represents a significant advancement in handheld laser welding technology. Its combination of welding and cleaning capabilities, along with its flexibility in handling various materials and thicknesses, make it a powerful tool for fabricators seeking efficiency, quality, and versatility. Whether you’re a seasoned professional or new to welding, the LightWELD XR is designed to enhance your welding projects with its innovative features and user-friendly operation.

FAQs

- What materials can the LightWELD XR weld?

The LightWELD XR can weld a variety of materials including aluminum, copper, stainless steel, titanium, and nickel alloys, and it’s also capable of welding dissimilar metals. - Is the LightWELD XR suitable for beginners?

Yes, it is designed to be user-friendly with a quick learning curve, making it suitable for both beginners and experienced operators. - How does the LightWELD XR compare in speed to traditional welding methods?

- The LightWELD XR is up to 4 times faster than TIG welding, offering significant improvements in welding speed while maintaining high-quality results.

- Does it require special safety equipment?

- Yes, operators should use laser safety glasses and protective clothing to guard against accidental laser exposure.

- Can the LightWELD XR perform cleaning operations?

- Yes, it features pre-weld and post-weld cleaning capabilities with up to 2500 W peak power, ensuring clean, strong welds.

- What is the power output of the LightWELD XR?

The LightWELD XR offers up to 2500 W peak power, with adjustable settings for various welding needs. - How does the wobble welding function enhance welding quality?

The wobble welding function allows for greater weld width and adaptability, improving weld strength and appearance by accommodating variations in joint fit-up.

We’re eager to hear from you! Share your experiences and thoughts about the LightWELD XR Handheld Laser in the comments below. Whether you’ve used it for intricate projects or heavy-duty tasks, your insights could be incredibly valuable to others considering this technology. Let’s help each other make well-informed decisions!

Jack Williams

Forestry AuthorI'm Jack Williams, Jack Williams, my expertise in welding and generator technologies extends beyond traditional boundaries. With over 13 years of experience, I have honed my skills in a range of heavy-duty equipment, focusing particularly on welding and power generation. My passion for nature and commitment to ecological sustainability inform my approach to work. I emphasize safety, efficiency, and staying current with technological advancements. Beyond my technical skills, I am dedicated to sharing knowledge and fostering environmental awareness, aiming to contribute positively to both the welding and generator operation industries.

Leave your comment