Hypertherm Powermax45 XP Plasma Cutter Review

- February 15, 2024

- 0 comment

Over the years, I’ve worked with a wide array of cutting tools, from simple, manually-operated torches to advanced, computer-controlled (CNC) machines. Among these, the Hypertherm Powermax45 XP plasma cutter has emerged as a particularly reliable and flexible piece of equipment within my collection. This review will focus on my hands-on experience with the Powermax45 XP. I aim to offer a thorough analysis of its operational performance, user-friendliness, and its comparative standing relative to other plasma cutters available in today’s market.

Specifications

- Max Cut: 5/8″ steel.

- Power: 200-240 V, 1/3-PH.

- Amps: 20-45.

- Duty Cycle: High duty cycle.

- Size & Weight: Compact and portable.

- Technology: Smart Sense™ tech.

- Applications: For cutting, gouging, marking.

- Item Weight: 36 pounds

- Product Dimensions: 17.4 x 6.8 x 14.1 inches

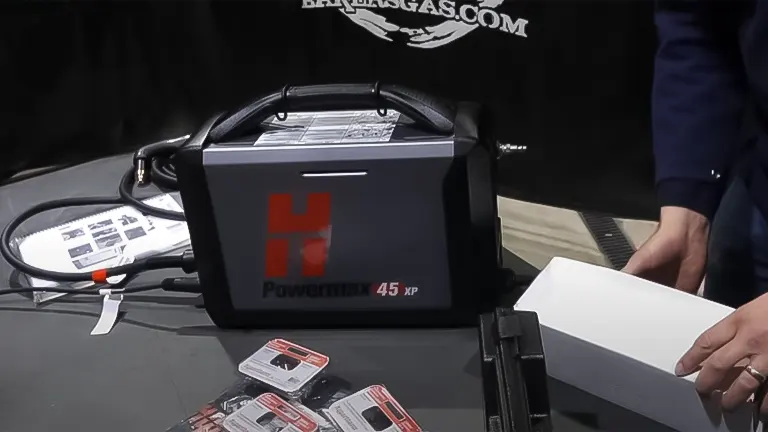

Unboxing and First Impressions

Upon opening the Hypertherm Powermax45 XP, the initial observation was its evident quality. The plasma cutter’s construction is sturdy, indicating its capability to withstand the rigors of heavy usage, yet its compact form factor hints at the manufacturer’s consideration for portability.

The process of setting up the machine was remarkably simple. The instructions provided were clear, and the machine’s design intuitive, facilitating a quick setup without any complications. This ease of setup indicated that I could start utilizing the machine without delay, setting a positive tone for its potential performance and efficiency in my projects.

Cutting Performance and Versatility

The Hypertherm Powermax45 XP’s cutting capabilities are notably impressive, with a maximum capacity of cutting through 5/8″ (16 mm) thick mild steel. This capacity is significant for a plasma cutter of its size, but what truly sets it apart is the quality of the cuts it produces.

The cutter achieves clean, precise cuts with minimal dross and slag, significantly reducing the time and effort required for post-cut cleanup. The availability of FineCut consumables enhances its utility for projects requiring high precision in cutting thin metals, essential for detailed and intricate work.

Additionally, the machine’s versatility extends beyond cutting; it is equally proficient in gouging, boasting a capability that competes with larger, more specialized equipment. This dual functionality has cemented its value in my workshop, allowing for a smooth transition between cutting and gouging tasks without the need to switch between different machines.

Durability and Reliability

The durability of the Hypertherm Powermax45 XP is one of its standout attributes. It has demonstrated an ability to endure prolonged and intensive use, maintaining consistent performance and reliability. This durability is a direct reflection of Hypertherm’s commitment to manufacturing products of high quality.

Furthermore, the integration of Smart Sense™ technology plays a crucial role in this reliability. By automatically adjusting the gas pressure, it not only ensures optimal cutting performance but also prolongs the lifespan of both the consumables and the machine itself. This technological feature underscores the cutter’s design focus on maintaining performance over time, making it a dependable tool for any fabrication environment.

Ease of Use and Duty Cycle

The Hypertherm Powermax45 XP is distinguished by its user-friendly interface, which simplifies the plasma cutting process, making it accessible to a broad range of users, from professionals to beginners. The automatic settings alleviate the complexity typically associated with plasma cutting, enabling users to achieve high-quality cuts without requiring extensive experience or knowledge.

Its lightweight and compact design enhance its usability by facilitating easy transportation and setup in various locations, whether within a workshop or on-site for external projects. This ease of use, combined with a high duty cycle, ensures that the Powermax45 XP can support extended operational periods, making it a highly flexible and efficient tool for a wide array of metal cutting and fabrication tasks.

Quantifiable Measurement

- Cutting Capacity 10/10: The Hypertherm Powermax45 XP can precisely cut through up to 5/8″ (16 mm) thick mild steel, showcasing its strong cutting performance.

- Power Requirements 9.5/10: It operates efficiently on 200-240 V, compatible with both 1-phase and 3-phase electrical supplies, highlighting its versatility in different setups.

- Weight and Dimensions 9/10: With a weight of 36 pounds and dimensions of 17.4 x 6.8 x 14.1 inches, the machine is portable and compact, making it suitable for various workspaces.

Visual Aspects Review

The Hypertherm Powermax45 XP showcases a sleek and industrial design, reflecting its robust functionality and professional-grade performance. Its compact and streamlined body, characterized by a combination of a dark and bright color scheme, not only makes it visually appealing but also emphasizes its durability and advanced technology.

The machine’s layout is thoughtfully designed with user accessibility in mind, featuring clearly labeled controls and an intuitive interface that enhances its visual ergonomics. This careful attention to design details ensures that the Powermax45 XP not only performs efficiently but also stands out in the workshop, marrying form with function in a way that is both practical and aesthetically pleasing.

What Sets Apart

What sets the Hypertherm Powermax45 XP Plasma Cutter apart from other plasma cutting systems is its exceptional combination of power, precision, and versatility. This cutter not only handles a wide range of cutting thicknesses with ease, up to 5/8″ (16 mm) for mild steel, but also delivers remarkably clean and dross-free cuts, minimizing the need for post-cut finishing.

Its unique Smart Sense™ technology automatically adjusts the gas pressure for optimal performance, enhancing both the quality of the cut and the lifespan of the consumables.

Additionally, the Powermax45 XP’s capability to perform not just cutting, but also gouging and marking, makes it an indispensable multi-functional tool for metalworking professionals.

Coupled with its robust design, user-friendly interface, and portability, the Powermax45 XP stands out as a top choice for those seeking efficiency, reliability, and superior cutting quality in their metal fabrication tasks.

Pros and Cons

Pros

- Exceptional Cut Quality: Delivers clean, precise cuts, reducing the need for additional finishing.

- Versatility: Effective for both cutting and gouging, suitable for a wide range of tasks.

- Durability: Constructed to withstand rigorous use over time.

- User-Friendly: Designed for ease of use, accommodating both experienced users and beginners.

- Portability: Lightweight and compact, facilitating easy transport and setup.

Cons

- Cost: The initial purchase price may be prohibitive for hobbyists or smaller operations.

- Consumable Expenses: The ongoing cost of consumables can accumulate, impacting long-term operational costs.

Maintenance of Hypertherm Powermax45 XP Plasma Cutter

Maintaining the Hypertherm Powermax45 XP Plasma Cutter is key to ensuring its efficiency, longevity, and operational safety. Proper maintenance can ward off common issues and maintain optimal performance. Here’s a detailed guide on how to keep your Hypertherm Powermax45 XP in top condition:

Before Each Use:

- Inspect for and tighten any loose connections or components to prevent operational hazards.

- Verify the torch and consumables are in good condition, replacing any worn parts to ensure clean, precise cuts.

- Check the air filter and compressor setup to ensure there’s adequate airflow for cooling and operation, which is crucial for preventing overheating.

- Ensure the machine’s software is up to date, if applicable, to take advantage of any performance improvements or bug fixes.

- Confirm that the grounding clamp is secure and in good condition for electrical safety and cutting efficiency.

Regular Maintenance:

- Clean the exterior of the cutter regularly to remove any debris or dust that could impede air circulation or accumulate in sensitive areas, potentially causing overheating or reduced efficiency.

- Regularly inspect and clean the air filtration system to maintain optimal airflow. A clogged filter can reduce performance and increase operational costs.

- Check and maintain proper gas pressure and flow rate as recommended by Hypertherm to ensure optimal cutting performance and to prolong consumable life.

- Monitor the condition of power cables and hoses for signs of wear, abrasion, or damage, replacing them as necessary to prevent electrical hazards and ensure consistent performance.

- Follow the recommended schedule for replacing consumables to maintain cut quality and machine performance, noting that the frequency will depend on usage patterns.

Long-Term Storage:

- Clean the machine thoroughly to prevent dust and debris buildup that could affect performance when the cutter is next used.

- Disconnect the power supply and store the cord securely to prevent damage.

- Cover the machine to protect it from dust and moisture if it will be stored in a workshop environment for an extended period.

- Ensure that the machine is stored in a dry, safe place to prevent accidental damage and to prolong its lifespan.

Safety Equipment Maintenance:

- Regularly inspect and maintain any safety equipment used in conjunction with the plasma cutter, such as protective eyewear, gloves, and respiratory protection, to ensure they are in good condition and provide the necessary protection.

Following these maintenance steps for your Hypertherm Powermax45 XP Plasma Cutter will help keep it running smoothly, extend its service life, and ensure that your cutting projects are both safe and high-quality.

Is It Worth the Buy?

Determining whether the Hypertherm Powermax45 XP Plasma Cutter is worth the investment hinges on your specific needs and applications. This machine offers exceptional cut quality, versatility in cutting and gouging, and a robust design built for longevity. Its user-friendly interface caters to both experienced professionals and newcomers to metalworking, while its portability allows for flexibility across various environments. Despite its higher price point and the ongoing cost of consumables, the efficiency, precision, and durability it provides can significantly enhance productivity and reduce long-term operational costs. For those seeking a high-performance, versatile plasma cutting tool that delivers on both quality and reliability, the Hypertherm Powermax45 XP presents a compelling value proposition.

Conclusion

The Hypertherm Powermax45 XP is a standout plasma cutter that excels in nearly every category. Its combination of power, precision, and versatility makes it an excellent choice for professionals looking for a reliable, high-quality cutting tool. While the initial investment may be higher than some alternatives, the performance and durability of the Powermax45 XP offer significant value over time. Whether you’re working on intricate artistic projects or heavy-duty industrial fabrication, the Powermax45 XP is a tool that can meet and exceed your expectations, making it the best overall choice in its category based on my experience and expertise.

Frequently Asked Questions

- What materials can the Powermax45 XP cut?

The Powermax45 XP can cut a wide range of materials including mild steel, stainless steel, aluminum, and more, with a maximum clean cut capacity of 5/8″ (16 mm) for mild steel. - Can the Powermax45 XP be used for tasks other than cutting?

Yes, it’s designed for versatility, capable of not only cutting but also gouging and marking, making it a multifunctional tool for various metalworking projects. - What power supply is needed for the Powermax45 XP?

It operates on both 200-240 V, compatible with 1-phase and 3-phase electrical supplies, offering flexibility for different workshop setups. - Is the Powermax45 XP portable?

Absolutely, with its compact size (17.4 x 6.8 x 14.1 inches) and light weight (36 pounds), it’s designed for easy transportation and setup in various environments. - What is the duty cycle of the Powermax45 XP?

The duty cycle varies based on the amperage and cutting conditions but is designed to support extended periods of operation, ensuring high productivity. - Does the Powermax45 XP come with a warranty?

Yes, Hypertherm offers a warranty for the Powermax45 XP, with specific terms and conditions available on their official website or through authorized dealers. - How user-friendly is the Powermax45 XP?

It is highly user-friendly, featuring an intuitive interface, automatic settings, and clear instructions, making it accessible to users of all skill levels. - Can the Powermax45 XP be used with CNC machines?

Yes, it is compatible with CNC interfaces, allowing for precise, automated cutting operations in addition to hand-held use. - What is Smart Sense™ technology?

Smart Sense™ technology automatically adjusts the gas pressure for optimal performance, enhancing cut quality and extending consumable life. - How do the ongoing costs for consumables compare with other plasma cutters?

While durable, the consumables for the Powermax45 XP may represent a recurring cost that is worth considering. However, the efficiency and extended life span of these consumables can offer value over time compared to some other plasma cutters.

We’re eager to hear from you! Share your personal experiences and insights about the Hypertherm Powermax45 XP Plasma Cutter in the comments section below. Your feedback could greatly assist fellow fabricators and metalworkers in making informed decisions!

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

Leave your comment