Wood-Mizer HR1000 Horizontal Resaw Review 2024

- June 23, 2023

- 0 comment

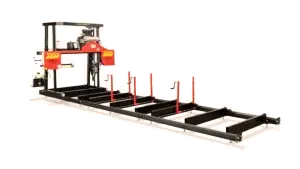

For anyone in the woodworking industry, having a high-performance and reliable resaw is the key to delivering top-notch results. In my quest to help fellow woodworkers identify the best equipment, I’ve turned my attention to the Wood-Mizer HR1000 Horizontal Resaw with 6 heads. Having had the opportunity to work with this machine firsthand, I’m eager to share a detailed and comprehensive review.

Specifications

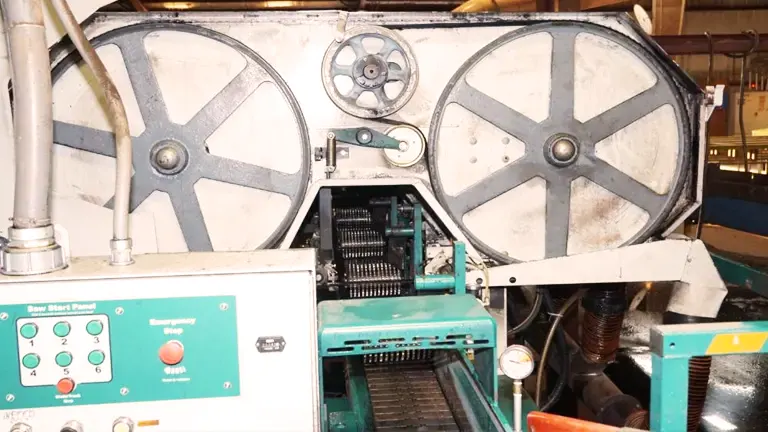

- Power: 25HP (18.6kW) electric motor

- Cutting Capacity:

- Maximum log diameter: 30.5 cm (12″)

- Maximum log length: 244 cm (96″)

- Maximum cutting width: 7.6 cm (3″)

- Blade:

- Blade length: 5.2 m (205″)

- Blade width: 32 mm (1.25″)

- Blade thickness: 0.89 mm (0.035″)

- Feed Speed: 0-100 ft/min (0-30 m/min)

- Other Features:

- Hydraulic blade tensioner

- Hydraulic feed system

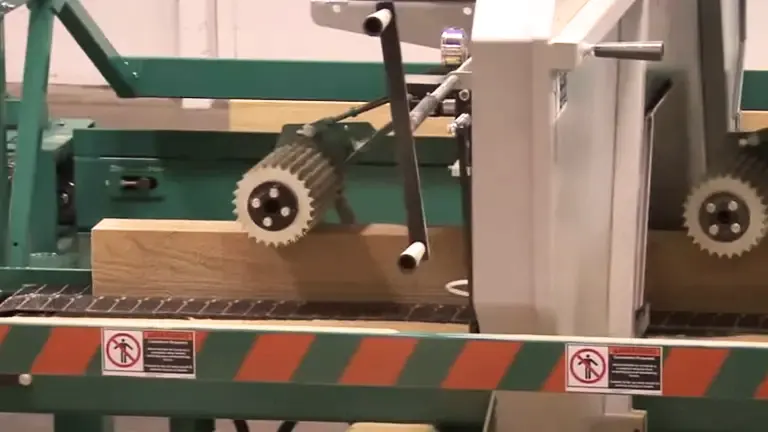

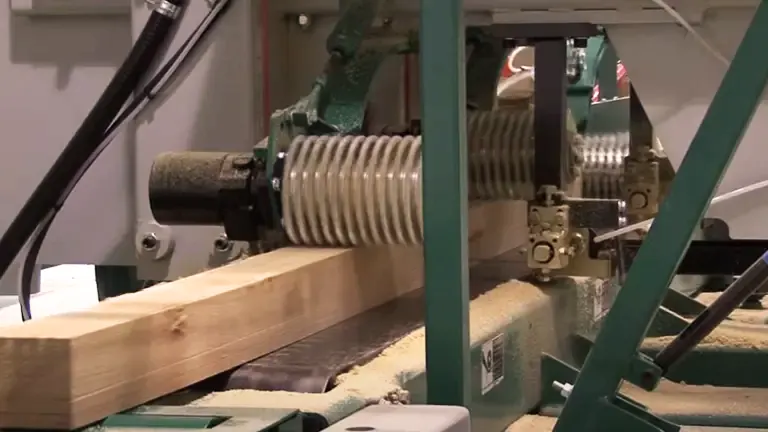

- Spiked feed rollers

- Steel belt conveyor

- Merry-go-round option (for automatic log turning)

Personal Experience

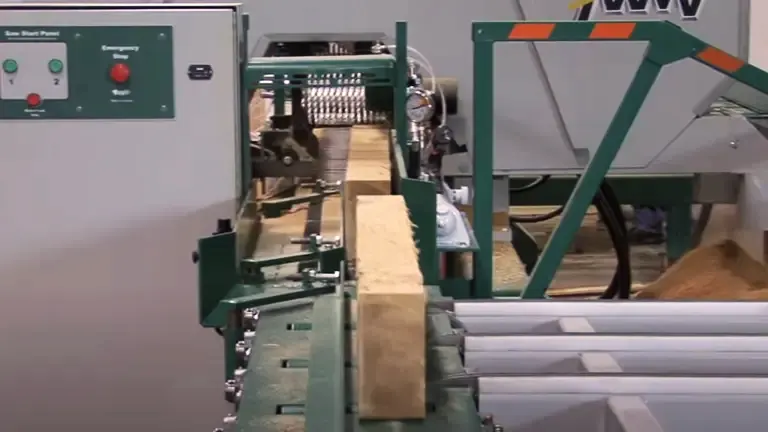

The first time I encountered the Wood-Mizer HR1000 Horizontal Resaw with 6 heads, it was a slightly intimidating sight. With its substantial size and the complexity of its multiple heads, I realized this was a piece of machinery that meant serious business. But once I began working with it, my apprehensions eased.

The user-friendly design was immediately apparent. The bed-level blade wheels were a godsend, simplifying the feed process considerably. In other resaws, maintaining a consistent feed can sometimes be a battle, but the HR1000 made the task almost effortless.

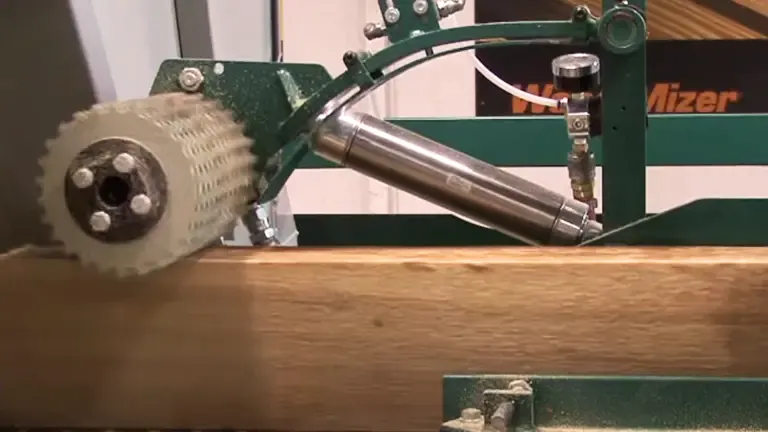

Then there was the adjustable blade guide arm. This feature made it easy to tweak the machine to handle different material sizes. It was simple to operate and saved a lot of time, particularly when I had a project that required varied dimensions.

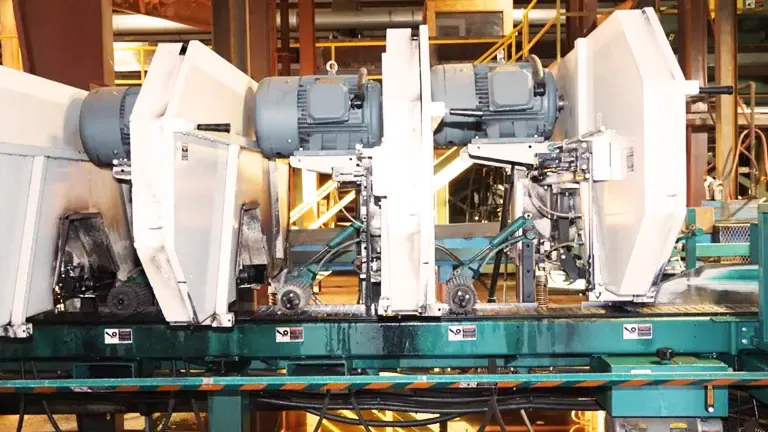

The HR1000’s six heads added another level of versatility that I found highly valuable. The option to use multiple blades simultaneously allowed for efficient batch processing of lumber, significantly reducing the total processing time. Each head could also be adjusted individually, providing a wide range of cutting options.

Operating the machine, I felt the power behind the 20HP main motor. It was more than capable of handling hardwoods, slicing through them with precision and efficiency. The additional 1HP feed motor maintained a smooth, consistent feed, allowing the main motor to focus on the cutting.

What surprised me most was the variable feed speed of up to 120 feet per minute. It outpaced many other resaws I’d worked with, allowing me to complete tasks much quicker than I’d initially expected.

Despite its initial intimidating presence, the Wood-Mizer HR1000 turned out to be a pleasure to work with. It combined power and versatility in a user-friendly design that made it a valuable asset in any serious woodworking setup. It demonstrated to me that sometimes, even in a field as traditional as woodworking, innovation can make a world of difference.

Performance Metrics and Features

With a 20HP main motor and an additional 1HP on the feed motor, the HR1000 cuts through materials with impressive speed and precision. But the machine isn’t only about power. The variable feed speed, reaching up to 120 ft/min, ensures that you can maintain quality even when working on time-sensitive projects.

As for blade options, the HR1000 accommodates both high-speed steel and carbide blades. This versatility means you can choose the blade that best suits the task at hand, whether it’s general-purpose cutting or working with harder wood types. During my time with the machine, I found that being able to switch between blade types significantly improved my work’s overall efficiency and quality.

Positioning the HR1000 Against Competitors

Navigating through the landscape of resaws, one can find numerous models and brands vying for attention. However, few manage to make a mark as prominent as the Wood-Mizer HR1000. When placed against other stalwarts like Baker and Select Sawmill, the HR1000 not only stands toe-to-toe but often surpasses them.

One of the defining attributes of the HR1000 is its variable feed speed, peaking at an impressive 120 feet per minute. Such a feature is not commonly found in all resaws. This capability, combined with its powerful 20HP main motor and an additional 1HP on the feed motor, allows the HR1000 to deliver a cutting speed that outstrips many of its competitors. This edge in speed can dramatically boost productivity, making the HR1000 an efficient choice for businesses aiming to scale their operations.

However, what truly distinguishes the HR1000 in a sea of competitors is its six-head system. While the industry standard typically revolves around single or dual-head systems, the HR1000 takes a leap forward by offering six heads. This design choice not only multiplies the machine’s versatility but also allows it to cater to a broader spectrum of projects.

The six heads work in harmony, each able to operate individually and adjust to different material sizes. This means users can simultaneously work on multiple pieces of lumber, each with varied thickness levels, without having to stop and adjust the machine each time. This feature drastically reduces the processing time, especially when working on large-volume projects.

The six-head system also allows for a wider variety of cuts on a single pass, which is incredibly valuable for custom jobs or unique project requirements. This adaptability provides an edge over more rigid, less accommodating models from competitors.

In conclusion, the Wood-Mizer HR1000 makes its presence felt in the resaw market by combining superior performance with enhanced versatility. It’s speed and unique six-head system not only set it apart from other resaws but also make it a versatile tool, ideal for a wide range of projects. This distinct edge makes it a formidable contender, one that’s well-equipped to meet and exceed the needs of serious woodworkers.

Pros and Cons

Pros

- High-Performance: With a 20HP main motor and 1HP feed motor, the HR1000 is designed to handle heavy-duty cutting tasks with remarkable efficiency and precision.

- Six-Head System: This feature stands out as a major advantage of the HR1000. The ability to adjust each head individually offers unparalleled flexibility, accommodating a wide range of material sizes and thickness levels.

- User-Friendly Design: The machine’s design prioritizes ease of use, with features like the bed-level blade wheels and an easily adjustable blade guide arm. This not only simplifies operations but also makes maintenance more manageable, reducing downtime and increasing productivity.

- Variable Speed: The HR1000’s variable feed speed, reaching up to 120 ft/min, ensures fast yet quality cuts, making it an excellent option for time-sensitive projects.

- Versatile Blade Options: The machine can accommodate both high-speed steel and carbide blades, allowing you to choose the blade that best suits your project.

Cons

- High Initial Cost: The HR1000’s price point, starting at around $33,000, might seem steep, especially for small-scale businesses or hobbyists. However, the machine’s superior performance and reduced maintenance needs can offset this cost over time.

- Space Requirements: Given its size and multi-head system, the HR1000 requires ample space for installation and operation, which could be a drawback for workshops with limited space.

- Training Required: Although the machine is user-friendly, the six-head system might require some training to operate efficiently, especially for users accustomed to single or dual-head resaws.

The Evolution of the HR1000

Wood-Mizer’s HR1000 is not just another product in the market; it is the manifestation of years of innovative thinking and careful design. This impressive machine stands on the shoulders of its predecessors, but it also goes several steps further.

The introduction of bed-level blade wheels is a revolutionary design feature that increases the ease of use significantly. The level blade wheels help facilitate a smoother material feed process, which reduces the strain on the operator and increases the efficiency of the operation.

Furthermore, the adjustable blade guide arm is another testament to Wood-Mizer’s innovative approach. This feature simplifies the process of setting the machine for different material sizes, enhancing its flexibility and versatility. By incorporating these enhancements, Wood-Mizer has managed to refine the usability and performance of the HR1000, making it a superior choice among horizontal resaws.

Pricing and Ideal Use Cases

The HR1000 does come with a significant upfront cost, with prices beginning around $33,000. While this might be considered a drawback, especially for smaller operations or hobbyists, it’s important to look at the bigger picture. The superior performance, reduced maintenance needs, and enhanced processing speed of the HR1000 can lead to significant cost savings over time, making the investment worthwhile.

The machine’s power and versatility make it ideal for professional woodworking shops or businesses that deal with high-volume work or varied project requirements. The six-head system provides a level of flexibility that is rarely matched by other resaws. It allows for a wide range of material sizes and thicknesses, making the HR1000 a versatile workhorse capable of handling virtually any task thrown at it.

Final Verdict

To wrap up, the Wood-Mizer HR1000 Horizontal Resaw with its 6-head system stands out not only as a high-performing, user-friendly machine but also as a smart investment for any serious woodworker or business. The design features and performance enhancements that Wood-Mizer has packed into the HR1000 make it a versatile and reliable tool capable of delivering excellent results across a range of projects.

Yes, its upfront cost is substantial, but the long-term benefits it offers in terms of time-saving, reduced maintenance, and improved processing capabilities offset the initial investment. So, whether you’re running a professional woodworking shop or a large-scale woodworking business, the HR1000 could very well be the smart investment that pays dividends for years to come.

Frequently Asked Question

- What is the Wood-Mizer HR1000 Horizontal Resaw with 6 heads?

The Wood-Mizer HR1000 Horizontal Resaw with 6 heads is a highly efficient and advanced sawing machine designed for cutting large timber into smaller boards or cants. It features six cutting heads arranged horizontally, allowing for the simultaneous cutting of multiple boards in a single pass. - What are the key features of the Wood-Mizer HR1000 Horizontal Resaw with 6 heads?

The Wood-Mizer HR1000 Horizontal Resaw with 6 heads comes with several notable features, including a heavy-duty construction, six horizontal cutting heads, a hydraulic feed system, a variable speed drive, a large cutting capacity, and a user-friendly control panel. - What is the cutting capacity of the Wood-Mizer HR1000 Horizontal Resaw with 6 heads?

The HR1000 Horizontal Resaw with 6 heads is designed to handle large logs with a maximum diameter of 42 inches (106 cm) and a width of 34 inches (86 cm). It can efficiently cut these logs into multiple boards simultaneously, maximizing productivity and yield. - How does the hydraulic feed system of the HR1000 Horizontal Resaw work with 6 heads?

The hydraulic feed system of the HR1000 Horizontal Resaw with 6 heads consists of top and bottom hydraulically powered feed rollers. These rollers advance the timber through the cutting heads at a consistent rate, ensuring precise and parallel cuts across all six heads. - Can the Wood-Mizer HR1000 Horizontal Resaw with 6 heads cut different types of wood?

Yes, the HR1000 Horizontal Resaw with 6 heads is designed to cut a wide range of wood species, including hardwoods, softwoods, and tropical hardwoods. It is suitable for processing logs into multiple boards simultaneously, catering to various woodworking applications. - Is the Wood-Mizer HR1000 Horizontal Resaw with 6 heads easy to operate?

Despite its advanced features, the HR1000 Horizontal Resaw with 6 heads is designed to be user-friendly. It features a control panel that allows operators to adjust the cutting speed, blade tension, and feed rate with ease. The intuitive controls and safety features make it accessible to both experienced operators and newcomers to woodworking. - Can the Wood-Mizer HR1000 Horizontal Resaw with 6 heads be customized or upgraded?

Wood-Mizer offers various optional upgrades and customization options for the HR1000 Horizontal Resaw with 6 heads. These may include additional safety features, extended tables for supporting longer timber, laser guide systems, and more, depending on your specific requirements. - What are the advantages of using the Wood-Mizer HR1000 Horizontal Resaw with 6 heads?

The HR1000 Horizontal Resaw with 6 heads offers several advantages, such as increased efficiency and productivity due to the simultaneous cutting of multiple boards, reduced labor requirements, enhanced accuracy and precision, and the ability to maximize the value and yield from raw timber materials. - Is the Wood-Mizer HR1000 Horizontal Resaw with 6 heads suitable for industrial use?

Yes, the HR1000 Horizontal Resaw with 6 heads is a robust and heavy-duty machine that is well-suited for industrial applications. It is built to withstand continuous operation, delivering reliable performance even in demanding production environments. - How can I get more information about the Wood-Mizer HR1000 Horizontal Resaw with 6 heads?

For more detailed information about the Wood-Mizer HR1000 Horizontal Resaw with 6 heads, including specifications, pricing, and availability, you can visit the official Wood-Mizer website or contact their sales representatives directly.

We’re eager to hear from you! Kindly take a moment to share your firsthand experiences and thoughts about the Wood-Mizer HR1000 Horizontal Resaw in the comments section below. Your insights could play a pivotal role in assisting others who are considering their options for resawing equipment in 2024. Let your review be a guiding light for those seeking efficiency and precision in their wood processing endeavors.

Leave your comment