The Overlooked Secret of the Stihl 4-Mix Engine

- April 1, 2024

- 0 comment

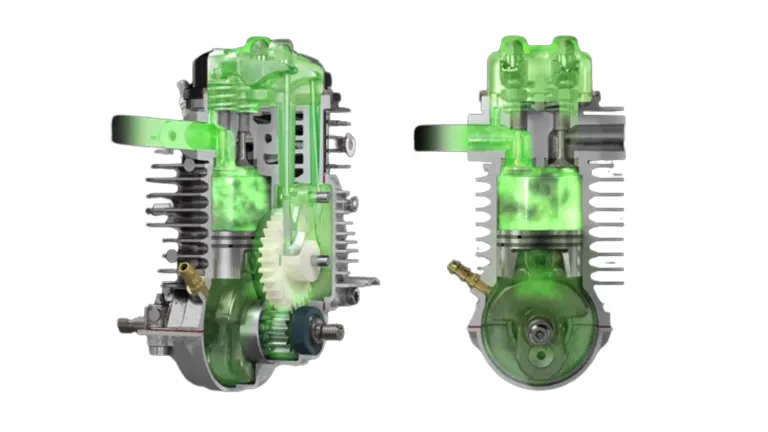

Dive into the world of Stihl 4-Mix engines to uncover the secrets of diagnosing air leaks, focusing on the vital role of the valve cover. Join us in mastering engine mechanics.

What is STIHL 4-MIX Engine?

The STIHL 4-MIX engine is a revolutionary design that merges the best of both two-stroke and four-stroke technologies. This engine stands out for its lightweight design, substantial lugging power, and superior torque. Its operation on a petrol-oil mix not only simplifies maintenance by eliminating the need for oil servicing but also adheres to stringent European Stage II exhaust emission standards, ensuring cleaner operation.

Key Benefits of the STIHL 4-MIX Engine:

- Achieves cleaner combustion with minimal residues, meeting strict environmental standards.

- Utilizes a standard petrol-oil mix, avoiding the complications of oil changes and disposal.

- Eliminates the need for an oil pump, sump, and oil tank, contributing to its lighter weight.

- Produces a more pleasant sound, even when running at full power.

- Offers impressive acceleration and high torque for demanding tasks.

Innovative Design Features:

- The engine uses a unique lubrication method where the petrol-oil mixture is channeled through the cylinder head, ensuring thorough lubrication of the engine’s components.

- A decompression system is integrated to facilitate easy starting, reducing the effort required to pull the starter rope.

With the STIHL 4-MIX engine, users can expect a high-performing, easy-to-maintain engine that combines the advantages of two-stroke and four-stroke engines, all while providing a lightweight and less noisy operational experience.

Insightful Tip for the Uninitiated

Alright, everyone, here’s a quick yet significant tip that many mechanics miss regarding the Stihl 4 Mix engine. When it comes to diagnosing an air leak in these engines, which have their unique valve systems, one critical area often gets overlooked: the valve cover.

You’ll know there’s an air leak because the engine will struggle, indicating it’s running lean due to unregulated air intake. While many will diligently check various parts, the valve cover frequently escapes scrutiny, yet it plays a crucial role.

Real-Life Revelation

I recall a time with a fellow mechanic who, upon seeing my method, casually inquired if I had tried adjusting the valves with the engine running. I hadn’t, and I suspected he hadn’t either. He asserted he did it regularly. To prove his point, he started the engine, removed the valve cover, and immediately, the engine’s behavior changed dramatically—it was a moment of revelation, illustrating the valve cover’s significant impact on the engine’s operation.

The Experiment Unveiled

To drive the point home, I demonstrated by starting the engine and allowing it to idle smoothly before I began to unscrew the valve cover. As soon as I compromised the seal, the RPMs surged, showcasing a noticeable air leak. This wasn’t just a trivial display; it highlighted the valve cover’s essential role in maintaining the engine’s air-fuel balance.

A Technical Perspective

Here’s something to ponder: unlike typical four-stroke engines, the Stihl 4-Mix’s design is unique. It lacks an oil sump and uses oil passages similar to a two-stroke engine for lubrication. This design quirk means the valve cover isn’t just a cover but an integral part of the engine’s intake and lubrication system.

Step-by-Step Guide: Inspecting and Troubleshooting the Valve Cover

Tools Needed:

- Screwdriver or wrench (depending on the model)

- New valve cover gasket (if replacement is needed)

- Flashlight or inspection light

- Clean cloth

Safety Precautions:

- Ensure the engine is turned off and cool before starting the inspection.

- Wear protective gloves and eyewear to prevent injuries.

- Work in a well-ventilated area to avoid inhaling fumes.

Inspection and Troubleshooting Steps:

- Begin with a visual check of the valve cover for any obvious signs of wear, cracks, or damage. Use the flashlight to illuminate hard-to-see areas.

- Using the appropriate tool, check if the valve cover is properly tightened. A loose valve cover can lead to air leaks.

- Carefully remove the valve cover to inspect the gasket. Look for any signs of deterioration, cracking, or flattening that could indicate a poor seal.

- If the gasket shows signs of wear, replace it with a new one to ensure a good seal.

- Wipe the mating surface on the engine and the valve cover with a clean cloth to remove any debris or oil residue.

- Place the new gasket in position and reinstall the valve cover. Tighten it evenly to the manufacturer’s specified torque to prevent warping or leaks.

- Start the engine listen for changes in the sound and check for smooth operation. Observe if the air leak symptoms persist.

Common Mistakes and Misconceptions

Mistakes

- Overlooking the Valve Cover: Many mechanics focus on more complex parts and overlook the simple valve cover as a source of air leaks.

- Over-tightening: Over-tightening the valve cover bolts can warp the cover or crush the gasket, leading to leaks.

Misconceptions

- “It’s Just a Cover”: Some mechanics underestimate the importance of the valve cover, not realizing it’s integral to the engine’s air management system.

- Interchangeability of Parts: Assuming that all 4-Mix parts are interchangeable can lead to using incorrect or ill-fitting valve covers or gaskets, causing leaks.

Clarifications

- The valve cover is crucial in maintaining the correct air pressure inside the engine, and any compromise in its integrity can lead to performance issues.

- Proper installation and regular inspection of the valve cover and its gasket are essential to ensure the engine runs efficiently and to prevent air leaks.

By understanding these steps and common pitfalls, mechanics can more effectively diagnose and resolve issues with the Stihl 4-Mix engine, ensuring optimal performance and longevity.

Conclusion and Takeaway

The lesson here is clear: when investigating air leaks, one must not overlook the valve cover, a component often underestimated in its importance for engine performance. My own experiences taught me this lesson the hard way. Sharing this knowledge could help others save time and avoid frustration.

To all mechanics out there delving into the mysteries of a Stihl 4-Mix engine, remember this insight about the valve cover. It might just be the missing piece in your diagnostic puzzle. Hopefully, this revelation aids in your mechanical endeavors, making your workday smoother and more efficient. Here’s to solving the enigmatic challenges of engine repair, one air leak at a time. Wishing everyone success in their troubleshooting adventures!

More Articles You Might Enjoy:

- How To Fix A Stuck Chainsaw Brake: Practical Solutions and Tips

- Hidden Greasing Spot on a Chainsaw

- How To Unflood Your Chainsaw Without Using Tools

- Hidden Risks of Cold Seizures in Chainsaws

- When to Replace Your Chainsaw Chain: Key Indicators and Tips

- Understanding the LA Setting on STIHL Chainsaws

FAQs

- Can a faulty valve cover lead to significant engine damage over time?

Absolutely! If ignored, a compromised valve cover can cause persistent air leaks, leading to an overly lean mixture. This condition can increase engine temperature and wear, potentially resulting in significant damage and reduced engine life. - How often should the valve cover and gasket be inspected or replaced to avoid air leaks?

It’s wise to inspect the valve cover and gasket at regular service intervals, typically every 50 hours of operation, or annually for less frequent users. Replacement depends on their condition; if signs of wear or damage are present, it’s time for a change. - Are there any specific signs that indicate an air leak from the valve cover?

Yes, symptoms include erratic idling, difficulty in adjusting the carburetor, an unexplained increase in RPMs, and sometimes a hissing sound near the valve cover area indicating escaping air. - Can I use any gasket material for the valve cover, or does it need to be specific to the Stihl 4-Mix engine?

It’s crucial to use the specific gasket designed for the Stihl 4-Mix engine. Using incorrect materials can result in improper sealing and lead to air leaks or other engine malfunctions. - What’s the impact of ambient temperature on air leaks related to the valve cover?

Ambient temperature can affect the engine’s thermal expansion and contraction, potentially influencing the seal integrity of the valve cover. In colder climates, materials may contract and loosen, while in hotter environments, expansion can cause additional stress on the seal. - Is there a way to test the valve cover’s seal integrity without dismantling the engine?

A common method is using a smoke machine or a spray designed to detect leaks. Apply the smoke or spray around the valve cover while the engine is running; escaping smoke or visible spray indicates a leak. - How does the valve cover design of the Stihl 4-Mix differ from traditional four-stroke engines, and why does it matter?

The Stihl 4-Mix combines elements of both two-stroke and four-stroke designs, requiring the valve cover to play a part in the engine’s lubrication process. This unique function makes it crucial to ensure its integrity for proper engine operation.

We’ve journeyed through the intricacies of the Stihl 4-Mix engine, uncovering the often-missed significance of the valve cover in preventing air leaks. Knowledge, as they say, is power, and in the world of mechanics, it’s also the key to efficiency and longevity of your equipment.

Now it’s your turn to chime in! Have you encountered similar issues with your Stihl 4-Mix, or do you have unique insights or questions about engine maintenance? Your experiences enrich the conversation and help us all learn more. Comment below to share your thoughts and stories. Let’s foster a community where every mechanic, novice or expert, can gain from shared wisdom. If you found this article enlightening, don’t hesitate to spread the knowledge by sharing it with fellow enthusiasts and mechanics. Together, let’s unravel more mysteries of mechanical engineering, one engine at a time!

David Murray

Forestry AuthorI'm David Murry, a forestry equipment specialist with a focus on chainsaw operation. With over 13 years of experience, I've honed my skills in operating and maintaining a wide range of machinery, from chainsaws to log splitters. My passion for the outdoors and commitment to sustainable forestry drive my work, which emphasizes safety, efficiency, and staying updated with industry advancements. Additionally, I'm dedicated to sharing my expertise and promoting environmental awareness within the forestry community.

Leave your comment