How To Build A Miter Saw Station

- November 28, 2023

- 4 comment

Woodworking combines precision and creativity, and having the right tools can make all the difference. If you’ve ever struggled with uneven cuts or managing long pieces of wood, it’s time to build your own DIY Miter Saw Station. A Miter Saw Workbench isn’t just a workspace upgrade it’s a game changer for improving cutting accuracy and efficiency in your projects. Imagine having a custom-built station designed to fit your workshop and streamline your workflow. In this guide, we’ll walk you through the process of creating a Custom Miter Saw Station that suits your needs. Whether you’re tackling small DIY projects or ambitious woodworking plans, this setup will help you work with confidence and precision. Let’s get started on turning your workspace into a hub of productivity and creativity!

What You Need To Know About Miter Saw Station

A Miter Saw Station is an essential addition for woodworking enthusiasts and professionals. It serves as a dedicated workspace for a miter saw a powerful tool used for precise angled cuts in wood and other materials. These stations typically feature a sturdy Miter Saw Workbench with supports and extensions to handle long pieces of lumber. Many designs also include fences and guides to help ensure accurate and consistent cuts, making it easier to tackle complex projects.

Beyond cutting, a DIY Miter Saw Station streamlines your workflow by offering a centralized spot for measuring, marking, and cutting materials. This keeps your workshop organized and efficient. Whether you’re working on a Custom Miter Saw Station for professional use or building one to improve your home projects, it’s a practical upgrade that enhances precision and safety while making woodworking more enjoyable.

Materials and Tools Needed When Building A Miter Saw Station

Building a miter saw station typically requires a combination of basic woodworking tools and some specialized tools to ensure accuracy and efficiency. Here’s a list of tools and materials you may need:

- Lumber: 2x4s are commonly used for the frame and structural components. The quantity will depend on the size and design of your miter saw station.

- Plywood: A 3/4-inch plywood sheet for the work surface and shelves. Ensure it is sturdy and flat.

- Screws: Various sizes of wood screws for attaching the frame, shelves, and work surface. Choose screws suitable for woodworking.

- Wood Glue: Strong wood glue to reinforce joints and add stability. Make sure it’s suitable for the type of wood you’re using.

- Paint or Finish (Optional): If you want to give your miter saw station a finished look, consider paint or a wood finish of your choice.

- Sandpaper: Sandpaper or a sanding block for smoothing rough edges and preparing the wood for finishing.

- Safety Gear: Safety glasses, ear protection, and a dust mask to protect yourself while cutting and sanding.

- Miter Saw: The star of the show! Choose a miter saw that suits your needs and fits well with the design of your station.

- Circular Saw: For cutting large sheets of plywood to size. A table saw can also be used if available.

- Drill: A power drill for making pilot holes and driving screws. Ensure it’s charged and equipped with the appropriate bits.

- Tape Measure: A reliable tape measure for accurate measurements during the planning and construction phases.

- Speed Square: A speed square helps ensure accurate angles and measurements, especially when making cuts with your miter saw.

- Clamps: Wood clamps are useful for holding pieces together while you secure them with screws or glue.

- Level: A level ensures that your miter saw station is even and stable.

- Pencil and Marking Tools: Pencils or markers for marking measurements and cut lines on the wood.

- Framing Square: A framing square helps ensure that your cuts and joints are at right angles, contributing to the accuracy of your miter saw station.

- Workbench or Sawhorses: A sturdy workbench or sawhorses provide additional support for assembling and working on your miter saw station.

- Jigsaw (Optional): If your design includes curved or intricate cuts, a jigsaw can be useful.

Ensure you have a clean and well-ventilated workspace, and always follow safety guidelines when using power tools.

Step-by-Step Process on How To Build A Miter Saw Station

Step 1: Gather Materials and Tools

Starting your DIY Miter Saw Station begins with gathering the right materials and tools. For the structure, you’ll need eight-foot 2x4s and a single sheet of 3/4″ plywood, which you’ll cut lengthwise. These materials will create a sturdy foundation for your Miter Saw Workbench.

Next, prepare your tools. Essential items include a tape measure for accuracy, a speed square for precise angles, a miter saw for custom cuts, a drill for driving screws, and a circular saw for general cutting. Clamps and a framing square can also be helpful but are optional based on your project needs. With these tools and materials ready, you’ll have everything you need to build a functional and efficient Custom Miter Saw Station tailored to your workspace.

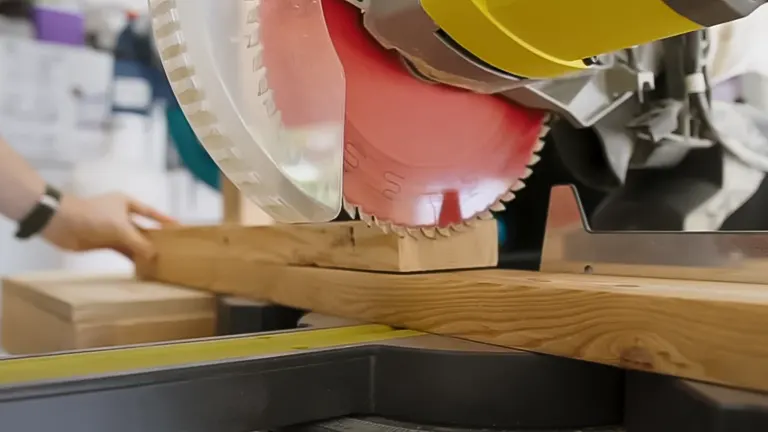

Step 2: Cut 2x4s to Length

Begin by cutting all 2x4s to the specified lengths based on your Miter Saw Station Plans. Precision is crucial at this stage to ensure a stable and well-fitted structure for your DIY Miter Saw Station.

Accurate cuts not only make assembly easier but also contribute to the overall durability of your Custom Miter Saw Station. By following the cut list carefully, you’ll ensure that each piece fits perfectly, laying a solid foundation for a reliable and efficient Miter Saw Workbench. This step sets the tone for the success of your woodworking project.

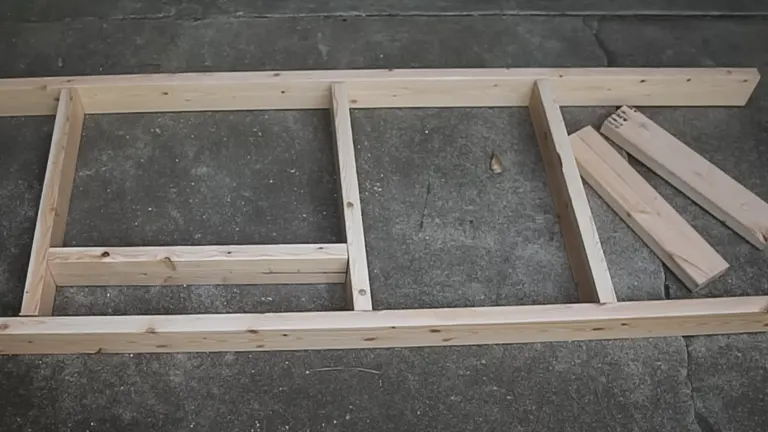

Step 3: Build the Right and Left Frames

Construct the right and left frames as separate components to simplify the assembly of your DIY Miter Saw Station. For the right frame, start by creating four legs with small feet at the base. Attach horizontal front stretchers across the tops of the feet, then add side stretchers along the inner sides of the legs. Finish the frame by securing a shorter leg riser on the left side and a longer one on the right. Repeat this process for the left frame, but reverse the placement of the leg risers.

Building the frames individually ensures a more organized and precise construction process. This methodical approach enhances the stability of your Custom Miter Saw Station, making it both durable and functional. By assembling each frame with care, you’ll create a solid foundation for an efficient and reliable Miter Saw Workbench.

Step 4: Attach the Frames Together

Position the left and right frames 24 inches apart to begin aligning your DIY Miter Saw Station. Place stretchers across the short leg risers and secure them with screws to establish a sturdy connection. This step is critical for the station’s structural integrity. Next, attach another stretcher at the rear’s bottom shelf level to provide additional stability and support for future components.

To enhance rigidity, install a cross brace at the center of the top stretchers, fastening it securely in place. This reinforcement ensures your Custom Miter Saw Station remains strong and stable, capable of handling the demands of daily woodworking. By carefully spacing and securing these elements, you’ll create a durable foundation for a reliable and efficient Miter Saw Workbench.

Step 5: Cut and Install Plywood Shelves and Work Surface

Start by measuring and cutting the bottom and top center shelves from a 24″ x 96″ plywood sheet to fit your Miter Saw Station Plans. Attach these shelves securely to the 2×4 stretchers, ensuring a snug fit that enhances the station’s stability and functionality. These shelves provide valuable storage and help keep your workspace organized.

Next, cut the top work surface from the remaining plywood, following dimensions tailored to your Custom Miter Saw Station. Secure the top surface to the 2×4 stretchers with screws, making sure it’s firmly attached along the front and back. This creates a flat, sturdy work area essential for precise cutting and other woodworking tasks. By carefully installing these plywood components, you’ll ensure your DIY Miter Saw Station is both durable and ready to handle your projects efficiently.

Step 6: Mount Your Miter Saw

Your DIY Miter Saw Station includes a practical 3 1/2″ recessed shelf designed to hold your miter saw. If your saw has a unique table height, adjust the shelf dimensions to ensure a perfect fit. Center the miter saw on the middle shelf with the handle extending outward for easy maneuverability. Secure the saw using long screws or lag bolts, matching the size and placement of the mounting holes on your saw.

This customizable design ensures that your Miter Saw Workbench can adapt to different saw models while maintaining functionality. Positioning the saw at the center optimizes access and usability, while proper fastening guarantees the stability needed for precise and safe cuts.

By building a Custom Miter Saw Station, you create a tailored workspace that significantly enhances your woodworking efficiency. Following these steps ensures a sturdy, practical station ready to support your miter saw and elevate your projects.

Tips on How to Maintain and Take Care a Miter Saw Station

- Regular Cleaning: Regularly sweep away the sawdust and bits around my miter saw and the station. I usually use a shop vac to get into the nooks and crannies, keeping things clean for precise cuts.

- Inspect and Tighten: If anything feels a bit loose, I grab my trusty wrench and tighten things up for stability.

- Lubricate Moving Parts: The moving parts of my miter saw get a dose of lubrication now and then. It’s like giving it a little massage to ensure it glides through cuts effortlessly.

- Blade Maintenance: After each project, I take a moment to clean my miter saw blade. If it’s been through the wringer, a bit of sharpening is in order. Happy blades make for happy woodworking.

- Check and Calibrate: I make a habit of double-checking the miter and bevel angles to keep my cuts on point. It’s like ensuring my saw is still grooving to the right tunes.

- Dust Collection System: If there’s a dust collection system in place, I make sure it gets its regular spa day. Emptying the dust bin and unclogging the hoses keeps everything running smoothly, much like a deep breath for my workspace.

- Organize Tools and Accessories: I’m a stickler for tool organization. It’s not just about keeping things neat; it’s about ensuring each tool has its place, so they’re always ready for action.

- Weather Protection: Since my workshop isn’t immune to the elements, I pay attention to humidity. A bit of wood sealing and rust-resistant coatings help my miter saw station weather any storm.

- Safety First: Every now and then, I run through the safety features. It’s like ensuring my miter saw is suited up with its safety gear—a little peace of mind goes a long way.

- Continuous Learning: I keep my ears to the ground for any new tips or tricks related to miter saws. Learning and adapting is part of the game, like discovering the latest dance moves for my saw.

By incorporating these maintenance practices into your routine, you’ll not only extend the life of your miter saw station but also create a safer and more efficient workspace for your woodworking projects.

Importance of Miter Saw Station in Woodworking

- Enhanced Precision and Accuracy: A miter saw station provides a stable and leveled platform for your miter saw, ensuring that every cut is executed with precision. The station’s design allows for accurate angle adjustments and consistent measurements, crucial for creating seamless joints and precise angles in your woodworking projects.

- Improved Workflow and Efficiency: One of the key advantages of a miter saw station is its ability to streamline your workflow. With a designated space for your miter saw, you can efficiently move through cutting tasks without the need to set up and take down your equipment repeatedly. This translates to significant time savings, allowing you to focus more on the creative aspects of your projects.

- Safety First: Safety should always be a top priority in any workshop. A miter saw station provides a secure and stable environment for operating your miter saw. The station’s structure minimizes the risk of vibrations or wobbling during cutting, reducing the likelihood of accidents. Additionally, a well-designed station often includes features like dust collection systems, contributing to a cleaner and safer workspace.

- Organization and Accessibility: Imagine having all your tools and accessories neatly organized within arm’s reach. A miter saw station typically includes shelves and storage compartments, providing a dedicated space for items like measuring tools, safety gear, and extra saw blades. This organizational aspect not only contributes to a clutter-free workspace but also ensures that everything you need is readily accessible.

- Customization for Unique Needs: Every woodworker has unique preferences and specific project requirements. Building your own miter saw station allows for customization to suit your individual needs. Whether it’s adding extra storage, incorporating features for special projects, or personalizing the station’s appearance, having a custom-built workspace enhances the overall woodworking experience.

- Consistency in Cuts: Consistency is key in woodworking, and a miter saw station helps maintain that consistency. Once the station is set up and calibrated, you can expect uniform and accurate cuts in every piece of wood you process. This not only saves time but also contributes to the professional quality of your finished projects.

In essence, a miter saw station is more than just a dedicated space for your saw—it’s a cornerstone for efficiency, safety, and creativity in woodworking. Whether you’re a seasoned woodworker or just starting, investing in a miter saw station is a step towards elevating the quality of your craftsmanship and making your woodworking journey more enjoyable.

Related Post

- 7 DIY Miter Saw Station Plans For Your Workshop

- Miter Saw Guide: Single VS Dual Bevel

- How to Adjust a Miter Saw for Accurate Cuts

- 5 Miter Saw Tips to Make Accurate Cuts

Conclusion

Building your own DIY Miter Saw Station is a rewarding project that transforms your workspace into a hub of efficiency and creativity. This guide provides a clear roadmap, from planning dimensions to assembling frames and mounting the miter saw, ensuring a sturdy and functional setup. Adding features like shelves and a reliable Miter Saw Workbench tailors the station to your unique needs, enhancing precision and organization.

Not only does a Custom Miter Saw Station improve your woodworking efficiency, but it also reflects your personal style and craftsmanship. By following these steps, you’ll create a durable, personalized workspace ready to support countless woodworking projects. Happy building, and enjoy the benefits of a station designed to fit your woodworking passion!

FAQs

- Can I customize the dimensions of the miter saw station to fit my specific workshop space?

Absolutely! In fact, customization is encouraged. Before starting the build, measure your workshop space and sketch a plan that aligns with those dimensions. This ensures the miter saw station seamlessly integrates into your workspace, optimizing both functionality and efficiency. - What’s the significance of adding a 3 1/2″ recessed shelf for the miter saw?

The recessed shelf serves a dual purpose. It provides a stable platform for the miter saw, ensuring it sits securely, and also aids in creating a level work surface. This design feature allows for easy movement of the miter saw while maintaining a consistent height with the surrounding work surface. - Can I use different types of wood for the construction of the miter saw station?

Certainly. While the guide suggests using 2×4 lumber and plywood, you have the flexibility to choose wood types based on your preferences and availability. Just ensure the selected wood is sturdy and can withstand the demands of a workshop environment. - Is it necessary to add a dust collection system to the miter saw station?

While not mandatory, incorporating a dust collection system is highly recommended for a cleaner and safer workspace. Sawdust accumulation can be a safety hazard and impact the accuracy of your cuts. Adding a dust collection system helps maintain a tidy environment and enhances overall safety. - Can I install additional features like a power strip or lighting in the miter saw station?

Absolutely! Customization is not limited to the basic structure. Adding features like a power strip for convenient tool access or lighting for better visibility are excellent ideas. Personalizing your miter saw station to suit your workflow and preferences enhances its functionality and makes it uniquely yours.

As you reach the end of this step-by-step guide on building a miter saw station, you now possess the knowledge and skills to create a dedicated and efficient workspace for your woodworking endeavors. Each stage, from planning to the final touches, has contributed to the realization of a practical and personalized station. With your newly constructed miter saw station, you’re not just equipped with a woodworking tool; you’ve crafted an integral space that fosters precision and creativity. Here’s to a future filled with successful projects in your newly organized and purposeful workshop. Happy woodworking!

Benjamin Brooks

Forestry AuthorGreetings! I'm Benjamin Brooks, and my journey over the past 15 years has revolved around the fascinating realms of content creation, expertise in snow clearing, and the intricate world of lumberjacking and landscaping. What began as a simple curiosity about the natural world and heavy machinery has evolved into a passionate profession where my love for crafting words intertwines seamlessly with my lumberjacking and garden skills.

4 comments

Are there plans for sale?

Steve Jenkins

December 3, 2023 11:09 pmThanks for the insight and inspiration to move forward with mine.

Stanley Sutton

December 2, 2023 3:58 pmDid I miss the “given cut list”?

I recently bought 3 acres with a 12x28 barn-style shed on it. I am planning on taking on the huge task of turning it into a tiny home. Thank you for the article. I have the saws (including a new table saw) and this gives me the encouragement to take the next big step to start making cabinets, etc.

Elizabeth Patrick

December 4, 2023 5:07 pm