When to Replace a Sawmill Blade?

- July 11, 2023

- 0 comment

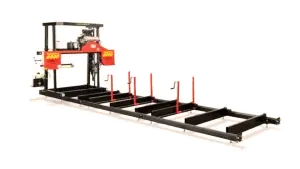

A smoothly running sawmill is an integral part of woodworking operations, with the sawmill blade being a critical component. Its condition directly impacts your output’s quality and your productivity. This thorough guide provides a clear understanding of when your sawmill blades may require replacement and also offers valuable suggestions to ensure its extended service life.

Signals That Your Sawmill Blades Needs Replacement

Declining Cutting Performance

When the blade is in its prime, it cuts through wood effortlessly and at a consistent speed. As the blade dulls, you may notice that it’s taking longer to cut through the same type of wood. Additionally, you might need to apply more force to push the wood through the blade. These are clear signs that the blade’s sharpness is fading, and it’s time to consider a replacement.

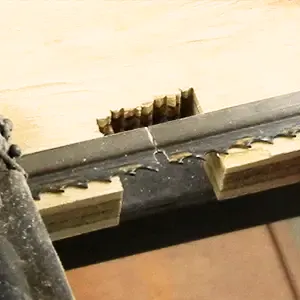

Modified Sawdust Characteristics

The nature of the sawdust produced during the cutting process can give you an insight into the blade’s condition. When a blade is sharp, it creates fine sawdust. But as it dulls, the sawdust becomes chunkier and more textured. By observing the sawdust, you can detect early signs of blade dullness.

Off-target Cuts

A fresh and well-maintained blade will cut accurately according to set dimensions. However, as the blade wears down, you may begin to notice deviations from your intended measurements. This lack of precision not only affects the quality of your work but is also an indication that your blade might be under strain and need replacement.

Unusual Noise and Vibration

A sawmill in good condition operates relatively smoothly, with predictable noise levels and minimal vibrations. If you start noticing increased noise or vibrations during operation, it could suggest that your blade has become dull or even damaged. A blade in such a state is likely to affect the sawmill’s efficiency and could potentially pose a safety risk.

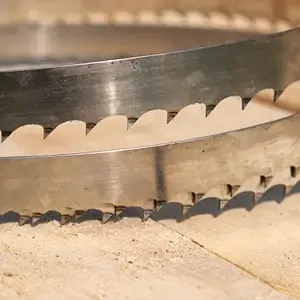

Visible Deterioration

Regular inspections of your sawmill blade can help identify signs of physical damage. This includes missing teeth, visible cracks, or any other structural damage to the blade. Such damage not only impacts the blade’s performance but can also be dangerous. If these signs are evident, it’s essential to replace the blade immediately.

Increased Energy Use

For electric or fuel-powered sawmills, one indication of a dull blade is an increase in energy consumption. A dull blade needs more power to cut through the wood because it’s not slicing efficiently. If you observe an unexplained rise in your power or fuel usage, it could be a sign that your blade needs replacement.

Changes in Blade Appearance

The physical appearance of a sawmill blade can tell a lot about its condition. Over time, the teeth of a blade may look rounded, shortened, or worn down. Additionally, the gullets – the spaces between the teeth – may be filled with sawdust, indicating that the blade isn’t cutting effectively. If you notice such changes, it’s probably time to replace the blade.

Inconsistent Cuts

If you find that your cuts are becoming wavy, or uneven, or the thickness of the boards is inconsistent, these are signs of a dull blade. A sharp blade should provide smooth, straight, and consistent cuts. Inconsistencies in your cut lumber suggest that it might be time to consider blade replacement.

Valuable Strategies to Prolong the Lifespan of Your Blade

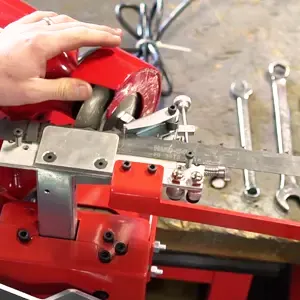

Regular Blade Sharpening

Keeping your sawmill blade sharp is a fundamental step in maintaining optimal cutting performance. Sharpening the blade involves removing a small amount of metal to restore the edge. This process extends the blade’s lifespan by keeping it in the best possible condition for efficient and safe cutting. It’s essential to follow the manufacturer’s guidelines or seek professional services for blade sharpening.

Consistent Cleaning

Sap, pitch, and other residues can accumulate on the blade over time, affecting its performance. By implementing a routine cleaning schedule, you can remove these substances, thus maintaining the blade’s cutting efficiency and preventing premature wear.

Appropriate Use of Lubricants and Coolants

Overheating is one of the significant factors that can reduce a sawmill blade’s lifespan. To avoid this, lubricants and coolants should be applied as per the manufacturer’s recommendations. These substances reduce the heat generated during cutting and lessen the friction between the blade and the wood.

Correct Blade Tensioning

The tension on a blade needs to be correctly balanced. If the blade is too tight, it may develop stress cracks; if it’s too loose, it can lead to inaccurate cuts. Adhering to the manufacturer’s guidelines for tensioning helps maintain the blade’s structural integrity and cutting accuracy.

Routine Blade Inspections

Regular inspections allow you to identify and address potential blade issues before they develop into major problems. This practice involves checking for signs of wear, damage, and build-up of residues. It helps to ensure that your blade is always in optimal working condition.

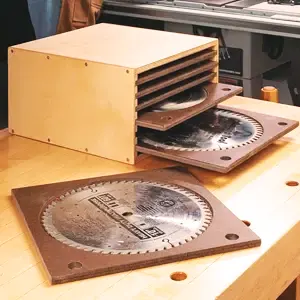

Proper Blade Storage

Correct storage of your sawmill blades is critical to prevent rust and corrosion. Blades should be stored in a clean, dry area and properly protected to prevent accidental damage.

Training for Operators

The sawmill blade’s lifespan can be greatly influenced by the operator’s handling. Proper training in blade handling and maintenance can prevent mishandling, which often leads to premature blade wear. It also promotes safer working practices.

Using Suitable Blades for Different Wood Types

Different woods have varying hardness and grain patterns, which can impact a blade’s wear. Using a blade designed for the specific type of wood you’re cutting can enhance its performance and reduce unnecessary wear.

Allowing Regular Breaks for Blades

Blades can overheat and wear out faster if used continuously for extended periods. Scheduling regular breaks during operation allows the blade to cool down, thus preventing overheating and extending its service life.

Avoid Cutting Dirty Wood

Cutting dirty or gritty wood can quickly dull your blade, leading to inefficient cuts and potential blade damage. If it’s essential to cut such wood, consider using a specific blade for this purpose and clean it regularly.

Invest in High-quality Blades

While they may have a higher upfront cost, high-quality blades are generally more durable, offer superior cutting performance, and yield smoother cuts. They may also require less frequent replacement, leading to long-term savings.

Timely Replacement of Damaged Parts

Damaged parts on your sawmill can put extra strain on the blade, leading to accelerated wear and potential damage. Regularly inspect your sawmill and ensure that all parts are in good working condition to prevent unnecessary stress on your blade

Troubleshooting Common Sawmill Blade Issues

Understanding how to recognize and address common blade issues is a crucial part of managing your sawmill. It not only promotes efficient operations but also helps to prolong the lifespan of your sawmill blades.

- Wavy Cuts: Wavy cuts often signify a dull or improperly tensioned blade. Regular blade sharpening and correctly tensioning the blade as per the manufacturer’s guidelines can resolve this issue.

- Crooked Cuts: This can occur if the blade guide is worn out or incorrectly set. Inspect the guide regularly for wear and ensure it is appropriately adjusted as per the manufacturer’s instructions.

- Excessive Blade Heating: Overheating is usually caused by improper use of lubricants or coolants or excessive feed rates. Using suitable lubricants and coolants, and moderating the feed rate can help prevent this issue.

- Premature Blade Dulling: Cutting dirty or gritty wood can lead to rapid blade dulling. Avoid cutting such wood where possible. If it’s unavoidable, regular cleaning and more frequent blade sharpening can help manage this issue.

- Uneven Wear: If your blade is wearing unevenly, it could be due to incorrect tracking or alignment. Regular inspection and adjustment of the tracking and alignment as per the manufacturer’s guidelines can mitigate this issue.

Related Articles:

- Best Uses And Ways To Dispose Slab Woods From Sawmill 2023

- Best Uses for Sawmill Off Cuts 2023

- 4 Best Slab Sawmills 2023

- Top 5 Affordable Sawmills: Balancing Cost and Performance

- The Best Sawmills for Your Homestead

- Best Sawmill Blades for Hardwood

- 10 Best Sawmill Bandsaw Blades

Selecting the Right Sawmill Blade

Choosing the right blade for your sawmill involves a careful evaluation of your needs, based on factors like the type of wood you’ll be cutting, the sawmill you’re using, and your desired output. Here are some suggestions that could guide you in making an informed decision:

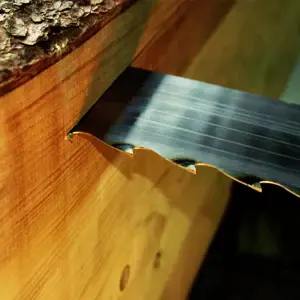

- Band Saw Blades: These blades are ideal for cutting a variety of wood types and provide clean, precise cuts. They’re also energy-efficient and tend to produce less waste compared to other blade types. The band saw blades are perfect for sawmill operators who prioritize precision and efficiency.

- Circular Saw Blades: For heavy-duty cutting and high-volume operations, circular saw blades are an excellent choice. They’re robust, durable, and capable of withstanding tough cutting conditions. However, they might produce rougher cuts and more waste compared to band saw blades.

- Carbide-Tipped Blades: Blades tipped with carbide are more durable than those made of regular steel, and they stay sharp longer. While they’re more expensive, they can handle harder woods and have a longer lifespan, offering better value over time.

- Rip Saw Blades: These are designed to cut with the grain of the wood (ripping). They have fewer, larger teeth that help remove more wood, making them ideal for sawmills that primarily rip lumber.

- Crosscut Saw Blades: If your sawmill operations often involve cutting across the grain of wood (crosscutting), you might want to consider crosscut blades. They have more teeth and offer a smoother finish than rip saw blades, making them ideal for creating finished products or for prepping wood that will be cut further.

Frequently Asked Questions

- How often should I sharpen my sawmill blade? The frequency of sharpening depends on the usage and the type of wood being cut. However, a good rule of thumb is to sharpen your blade after every few hours of cutting time. If you notice any change in performance or cut quality, it might be time to sharpen the blade.

- Can I sharpen my sawmill blade myself? Yes, it’s possible to sharpen your sawmill blade yourself. However, it requires a special sharpener and a good understanding of the blade’s design to maintain its precision. Incorrect sharpening can potentially harm the blade and affect its performance.

- How can I prevent my sawmill blade from rusting? Proper storage is the key to preventing rust. After use, clean the blade thoroughly and dry it completely before storing it. Keeping it in a dry, cool area away from direct sunlight can help prevent rusting. Some operators also apply a thin layer of oil for added protection.

- Can I use the same sawmill blade for different types of wood? While it’s possible, it’s not recommended. Different types of wood have different densities and hardness, and using a blade not designed for a particular type of wood can lead to inefficient cutting and faster blade wear.

- How can I tell if my blade tension is correct? Most sawmill manufacturers provide specific guidelines for blade tensioning. If these aren’t followed, you might notice the blade slipping or producing inaccurate cuts. A blade tension meter can provide a more precise measurement.

- Can I still use a sawmill blade if a tooth is missing? Using a blade with a missing tooth is not recommended as it can cause the blade to cut unevenly and could potentially be a safety hazard. It’s best to replace the blade if any teeth are missing or severely damaged.

- Why is my sawmill blade overheating? Overheating can be caused by several factors, such as a dull blade, incorrect feed speed, or insufficient coolant. Regular blade maintenance, correct operating techniques, and the appropriate use of coolants can help prevent overheating.

We’re eager to tap into your expertise! If you’ve got insights about the optimal time to replace a sawmill blade, we invite you to share them in the comments section below. Your practical wisdom could be a game-changer for fellow sawmill operators who are navigating the crucial decision of blade replacement. Whether it’s signs of wear and tear, diminished performance, or specific usage thresholds, your knowledge could empower others to make timely and informed choices. Join the conversation and help us keep the sawmill community cutting smoothly!

David Murray

Forestry AuthorI'm David Murry, a forestry equipment specialist with a focus on chainsaw operation. With over 13 years of experience, I've honed my skills in operating and maintaining a wide range of machinery, from chainsaws to log splitters. My passion for the outdoors and commitment to sustainable forestry drive my work, which emphasizes safety, efficiency, and staying updated with industry advancements. Additionally, I'm dedicated to sharing my expertise and promoting environmental awareness within the forestry community.

Leave your comment