Mastering Pipe Welding: Essential Tips and Techniques

- January 4, 2024

- 0 comment

Stick welding, also formally referred to as Shielded Metal Arc Welding (SMAW), stands out as a widely utilized welding technique for connecting pipes. The materials associated with SMAW are renowned for their simplicity and portability, contributing to the accessibility and cost-effectiveness of stick welding, making it an attractive option for both beginners and seasoned welders alike.

In contrast to alternative welding methods, stick welding distinguishes itself by not necessitating any shielding gas or flux during the welding process. This characteristic adds to its user-friendly nature and eliminates the need for additional equipment, simplifying the overall welding setup.

Various trades professionals leverage the advantages of stick welding for diverse applications, including but not limited to construction sites, gas and oil stations, and fabrication shops. The versatility of stick welding makes it a preferred choice in scenarios where mobility and ease of use are paramount.

Despite its reputation as a more straightforward and less demanding welding method, achieving successful results with SMAW still requires a high level of precision and meticulous attention to detail. Welders must adhere to certain tips and techniques to optimize their stick welding performance and ensure the integrity of the welded joints. In the following sections, we’ll delve into five valuable stick welding tips that welders can incorporate into their practices for enhanced and reliable outcomes.

Listing of Mastering Pipe Welding: Essential Tips and Techniques:

- Adhere to Essential Safety Measures

- Allocate Sufficient Time for Thorough Preparation

- Recall To Clams

- Vigilantly Watch for Common Errors

- Familiarize Yourself with Various Stick Welding Positions

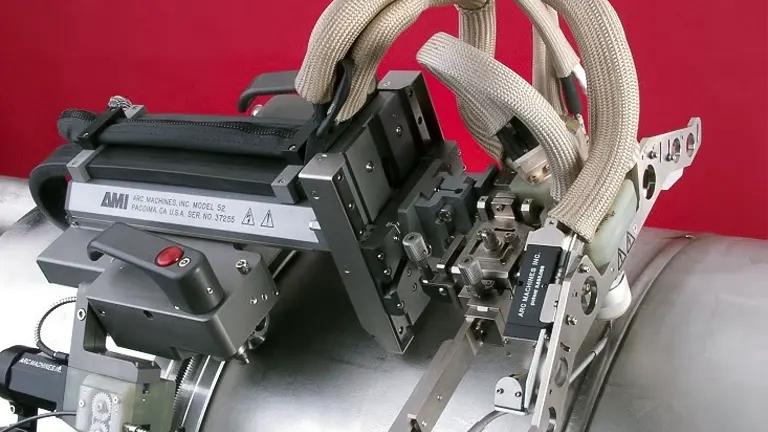

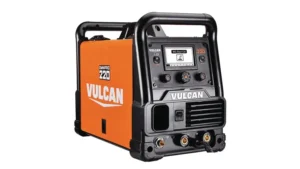

Welding Equipment: The Crucial Element for Welding Excellence

In the realm of welding, the prowess of a skilled welder is inseparable from the quality of the equipment they wield. It is a universally acknowledged truth among welding professionals that the right tools can make or break the success of a welding project. Drawing from my extensive experience, I emphasize the paramount importance of investing in a welding machine that is not just reliable but also boasts adjustable settings.

The crux of this lies in the ability to tailor the welding parameters precisely to the demands of a given task. A welding machine with meticulous amperage control and the capability to accommodate various welding processes, such as TIG, MIG, and Stick, is indispensable. This versatility empowers welders to seamlessly transition between different welding scenarios, particularly crucial in the dynamic field of pipe welding.

Whether tackling intricate joints, thick materials, or diverse metals, the adaptability of a high-quality welding machine lays the foundation for successful and efficient pipe welding. It becomes the artisan’s brush, allowing for the finesse required to create welds that not only meet but exceed industry standards.

1. Adhere to Essential Safety Measures

Welding professionals encounter a spectrum of potential hazards in their occupational landscape, ranging from intense light that can cause temporary blindness to exceedingly high temperatures and the presence of heavy objects. Given the inevitability of these risks, it becomes imperative for individuals in the welding field to undertake essential precautions to mitigate the likelihood of injuries and enhance the overall quality of their work.

Neglecting fundamental safety protocols can amplify the risk of errors and accidents. While specific safety guidelines may differ depending on the nature of each project, welders should consistently equip themselves with the following materials when engaging in stick welding:

- Heat-resistant gloves

- Protective goggles

- Safety shoes

- Non-flammable clothing

- Ventilation fan

- Fire extinguisher

The Symphony of Alloys: Stainless Steel, Carbon Steel, and Aluminum

Embarking on the journey of welding mastery requires a keen appreciation for the symphony of alloys at one’s disposal. Stainless steel, with its corrosion resistance and aesthetic appeal, contrasts with the robust strength of carbon steel, while aluminum introduces a dimension of lightweight versatility. Each alloy represents a unique chapter in the welder’s repertoire, offering distinctive advantages and presenting challenges that demand a nuanced approach.

Through a blend of exhaustive research and practical application, I’ve gleaned the crucial lesson that the choice of filler material is the linchpin in the welding process. It’s not merely about connecting two metal pieces; rather, it’s an artful amalgamation of science and craftsmanship, where the selection of the right filler material becomes the brushstroke that defines the quality and integrity of the final weld.

2. Allocate Sufficient Time for Thorough Preparation

Even the most proficient stick welders may encounter challenges in achieving their objectives if they neglect the essential step of thorough preparation. The preliminary phase of setting up plays a pivotal role in establishing the trajectory for the entire welding process.

While the specific requirements for a meticulous setup in stick welding may differ for each project, it is imperative to consider certain key elements before initiating the welding process:

- Choosing the right type of steel for stick welding.

- Clearing the piping of any dust, dirt, or other imperfections.

- Picking the correct electrode for the job.

- Getting in a comfortable and manageable position.

Meticulous Joint Preparation: A Prerequisite for Impeccable Welds

Embarking on the journey of achieving impeccable welds demands an unwavering commitment to meticulous joint preparation, often heralded as the foundational cornerstone of welding success. Drawing from my extensive experience, it becomes evident that the very essence of a flawless weld lies in the careful orchestration of the preparatory steps.

The significance of thorough cleaning and beveling of pipe ends cannot be overstated. These seemingly mundane tasks form the bedrock of a successful welding endeavor, ensuring that the welding process commences on a canvas free from contaminants and imperfections. In the intricate dance of welding, achieving the correct fit-up and ensuring proper alignment emerge as non-negotiable elements in the quest for perfection.

The meticulous nature of joint preparation extends beyond the surface, delving into the intricate details of alignment, which is paramount for a weld that not only meets but surpasses industry standards. As a testament to this, I have consistently observed that a dedicated focus on joint preparation serves as a robust defense against potential defects, elevating the overall weld quality and contributing to the longevity and structural integrity of the final product.

3. Recall To Clams

No, we’re not referring to the delectable shellfish. CLAMS serves as a mnemonic device crafted to assist welders in retaining the fundamental parameters crucial for executing a stellar stick weld. This memory aid proves invaluable in ingraining the essentials of the Shielded Metal Arc Welding (SMAW) technique. Let’s delve into what each letter of CLAMS represents:

- Current Settings: The configuration of current settings plays a pivotal role in determining the amperage that powers the welding stick. As each welding project has distinct requirements, adjusting the amperage accordingly is paramount. Mismatched currents can lead to undesirable outcomes, such as sticky electrodes with insufficient power or excessive fluidity when the power is overly high.

- Length of Arc: The length of the arc emerges as another critical factor influencing the quality of stick welds. An excessively long arc can result in heightened spatter production, while an undersized arc may lead to extinguished arcs or the formation of high-crown welding beads. A general guideline is to opt for an arc length no larger than the electrode’s core size.

- Angle of Travel: The electrode’s position during welding holds significant implications for weld quality. Vertical welding necessitates a pushing motion while tilting the electrode 0 to 15 degrees away from the travel direction. Conversely, when horizontally welding from left to right, the electrode should remain perpendicular to the pipe with a 5 to 15-degree tilt toward the travel direction.

- Manipulation: Manipulation refers to how welders utilize the electrode in the welding process. Various styles of manipulation exist, with seasoned welders developing their unique techniques. Novice welders can initially emulate the approaches of experienced counterparts to grasp effective methods before refining their personalized technique.

- Speed: Optimal speed in wielding the welding stick results in a well-developed crown and a moderate width of the weld. Welding too slowly can yield flatter, wider welds, while excessive speed can lead to shallow, convex-shaped beads. Maintaining the arc at the edge of the welding pool throughout the process is crucial for achieving optimal results.

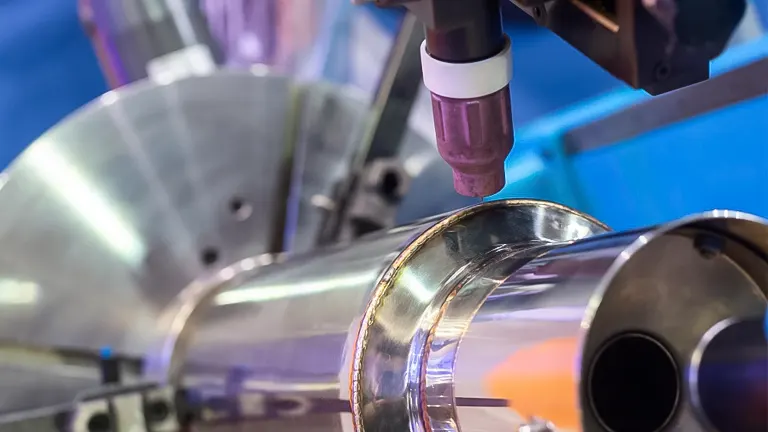

The Artistry of Pipe Welding Techniques: A Symphony of Precision

Embarking on the journey of mastering pipe welding unveils a complex yet beautifully orchestrated dance involving the intricate interplay of heat control, travel speed, and electrode manipulation. From my extensive hands-on experience, I’ve come to appreciate the nuanced artistry required to navigate this delicate dance effectively. Maintaining a consistent arc length emerges as a pivotal aspect, serving as the heartbeat of the welding process.

The art lies in the seamless coordination between heat intensity and electrode movement, creating a rhythmic harmony that ensures both aesthetic appeal and structural integrity. This dance is not merely about melting metal; it’s an artful pursuit of controlling the molten puddle, delicately shaping it to form a robust, uniform bond that withstands the test of time.

Precision in weaving patterns becomes a signature move in the pipe welding ballet. Each pass of the electrode contributes to the overall composition, determining the strength and appearance of the final weld.

The delicate balance between technique and finesse transforms the welding process into true craftsmanship, where the welder acts as both conductor and dancer. Through this intricate dance, the molten metal transforms from a raw material into a work of art, solidifying the connection between pipes with a strength that surpasses mere functionality. The techniques employed in pipe welding transcend the mundane; they embody a delicate symphony that elevates welding from a skill to an art form.

4. Vigilantly Watch for Common Errors

An integral aspect of mastering the stick welding technique involves the ability to discern prevalent mistakes and implement necessary corrections promptly. The swifter one can identify an issue, the greater the likelihood of enhancing the overall weld quality. Let’s delve into some of the typical problems associated with Shielded Metal Arc Welding (SMAW) that demand close scrutiny, along with their likely origins.

- Undercut Formation: An undercut manifests as a concave groove in the weld between connected pipe segments, diminishing the strength of the SMAW weld. This issue may arise when the amperage is set excessively high, leading to the formation of a crater in the welding pool.

- Inconsistent Arc Initiation: Smooth and consistent arc initiation is crucial in stick welding. If you encounter challenges in starting the arc, adjusting the amperage to generate a more potent arc is a potential remedy to explore.

- Excessive Splatter: The presence of excessive splatter can swiftly compromise an otherwise robust stick weld. Potential causes include utilizing an overly long arc or operating with an amperage set too high, both contributing to increased splatter during the welding process.

- Misshaped Weld Bead: A proficient SMAW technique typically yields a welding bead approximately 2.5 times the diameter of the electrode. Irregularities in the bead shape, such as bumps, may result from pulling too slowly or employing low amperage. Conversely, thin weld beads can form when pulling too quickly during the welding process. Identifying and rectifying these issues promptly is pivotal for maintaining the integrity and quality of the stick weld.

Navigating the Complexity of Pipe Welding Positions: A Skillful Endeavor

Mastery in pipe welding extends beyond the art of fusing metal; it encompasses the ability to adapt seamlessly to diverse welding positions. Each welding project presents a unique challenge, necessitating welds in horizontal, vertical, or even overhead positions. A skilled pipe welder understands the importance of being proficient in all these positions, marking a significant milestone in their expertise.

Drawing from my personal journey, I’ve come to appreciate the invaluable experience gained by deliberately practicing in different orientations. It’s not merely a quest for versatility but a strategic endeavor to elevate one’s skill set and fortify against the uncertainties inherent in real-world welding scenarios.

The mastery of welding positions is akin to a craftsman honing various techniques to carve a masterpiece – it is an indispensable aspect of achieving excellence in the intricate realm of pipe welding. Engaging with welding challenges in different positions is akin to a comprehensive training ground, where every angle and orientation becomes a lesson in adaptability.

The unpredictability of real-world welding scenarios demands a versatile skill set, and adeptly navigating through horizontal, vertical, and overhead positions is a testament to a welder’s prowess. It’s not merely about meeting the immediate demands of a project but about cultivating a holistic understanding of the welding process.

Through intentional practice in varied positions, a skilled pipe welder hones their ability to manipulate heat, control the molten puddle, and ensure consistent weld quality, irrespective of the gravitational challenges imposed by different welding orientations.

5. Familiarize Yourself with Various Stick Welding Positions

Determining the optimal method for stick welding is contingent on the specific requirements of the task at hand. Shielded Metal Arc Welding (SMAW) is an adaptable and dynamic pipe welding technique applicable in diverse settings. Consequently, various stick welding positions have evolved over time to address distinct welding challenges. Another crucial piece of advice among the top stick welding tips for pipes is to comprehend and master these diverse welding positions.

- Horizontal: Among the more straightforward stick welding positions, the horizontal orientation involves the welding axis lying flat. Welders execute this method when the pipe is positioned horizontally, necessitating specific techniques for achieving optimal weld quality.

- Vertical: True to its name, the vertical weld position sees the welding axis aligned in a vertical direction. Welders working in this orientation encounter specific challenges, including managing falling molten metal. Recognizing and implementing specialized vertical stick welding tips becomes imperative for success in this position.

- Flat: Commonly referred to as downhand welding, the flat position involves welders working on the upper side of the piping joint, with the axis of the weld running parallel to the weld’s length. Mastery of techniques applicable to this position is crucial for achieving precision and consistency.

- Overhead: Regarded as one of the more challenging stick welding positions, overhead welding necessitates trades professionals to operate from the underside of a pipe joint. This position introduces unique difficulties, demanding a high level of skill and precision from welders to navigate successfully.

Common Pitfalls and How to Avoid Them

No review would be complete without addressing the challenges faced in mastering pipe welding. From my own experiences and those shared by fellow welders, I’ve compiled a list of common pitfalls. Whether it’s insufficient penetration, improper cleaning, or inadequate preheating, recognizing these issues and learning how to avoid them is crucial for continuous improvement.

Related Articles:

- First Welder Guide for DIYers: Practical Tips

- Best 5 MIG Welders: From Budget-Friendly to Premium Picks

- Best Black Friday Welding Machine Deals 2023

- Troubleshooting Common Welding Machine Problems

- Best TIG Welder for the Money: Your Ultimate Buying Guide

- Best TIG Welder for Beginners

- Underwater Welding: Techniques, Risks, and Impacts on Structural Durability

Final Concluding Thoughts

In the realm of pipe welding, mastery is an ongoing journey. From the equipment you choose to the techniques you employ, every decision plays a role in the quality of your welds. Through my own trials and triumphs, I’ve come to appreciate the artistry and precision required in this craft. Remember, it’s not just about joining pipes; it’s about creating connections that withstand the test of time. So, equip yourself with the right knowledge, embrace the challenges, and keep welding – the path to mastery is a rewarding one.

Frequently Asked Questions

- What is the significance of welding equipment in pipe welding success?

Welding equipment serves as the foundation of successful pipe welding, impacting the quality and adaptability of the welds. Investing in reliable machines with adjustable settings is crucial for optimal results. - Why is choosing the right filler material essential in pipe welding?

The choice of filler material is akin to selecting the perfect tool for an artistic endeavor. Different projects demand distinct filler materials, each with its unique properties. The right choice is pivotal for welds to meet industry standards. - What role does joint preparation play in achieving flawless welds?

Joint preparation is the cornerstone for flawless welds, involving thorough cleaning, beveling, and proper alignment. Meticulous preparation significantly reduces the likelihood of defects and enhances overall weld quality. - How does CLAMS aid in optimizing stick welding performance?

CLAMS (Current Settings, Length of Arc, Angle of Travel, Manipulation, Speed) is a mnemonic device designed to help welders remember fundamental parameters for stick welding. It guides in maintaining the correct settings and techniques for a successful weld. - Why is it crucial to keep an eye out for common stick welding mistakes?

Identifying and correcting common mistakes promptly is essential for improving weld quality. Common issues include undercut formation, inconsistent arc initiation, excessive splatter, and misshaped weld beads. - How does practicing in different welding positions enhance a welder’s skill set?

Proficiency in various welding positions, such as horizontal, vertical, flat, and overhead, is indicative of a skilled pipe welder. Practice in different positions enhances adaptability and prepares welders for real-world welding challenges. - What is the delicate dance involved in pipe welding techniques?

Pipe welding techniques require a delicate balance between heat control, travel speed, and electrode manipulation. Maintaining a consistent arc length and precise weaving patterns are crucial for producing both aesthetically pleasing and structurally sound welds. - How does thorough preparation contribute to successful stick welding?

Thorough preparation, involving adequate setup time, sets the tone for the entire stick welding process. It ensures a clean canvas free from contaminants, reducing the chances of mistakes and enhancing overall weld quality. - Why is adaptability to different welding positions essential for a pipe welder?

Different projects demand welds in various positions, and being proficient in all positions is indicative of a skilled pipe welder. Adapting to different orientations enhances a welder’s versatility and readiness for diverse welding scenarios. - What are the key considerations when selecting welding positions for stick welding?

Stick welding positions include horizontal, vertical, flat, and overhead. Each position presents unique challenges, and understanding the nuances of each is crucial for executing successful stick welds.

Join the conversation! Feel free to share your firsthand experiences and insights on mastering pipe welding in the comments below. Your valuable input might be just the advice someone else needs to enhance their welding skills. Let’s build a community of knowledge and expertise together!

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

Leave your comment