The 13 Different Types of Wood Joinery 2024

- August 2, 2023

- 1 comment

Woodworking is an ancient craft that has stood the test of time, producing functional and artistic creations from one of nature’s most versatile materials: wood. To join pieces of wood together, various woodworking joints have been developed over the centuries. Each joint serves a specific purpose, ranging from simple and utilitarian connections to intricate and elegant designs that showcase the skill and craftsmanship of the woodworker.

These wood joints are crucial in woodworking projects, as they determine the strength, stability, and overall appearance of the final piece. Understanding the different types of wood joints empowers woodworkers to select the most appropriate joint for each project, ensuring that the finished product meets the desired requirements.

13 Different Types of Joinery Wood Joints:

- Butt Joint

- Rabbet Joint

- Miter Joint

- Lap Joint

- Dado Joint

- Spline Joint

- Mortise and Tenon Joint

- Tongue and Groove Joint

- Finger Joint

- Dovetail Joint

- Dowel Joint

- Cross Dowel Joint

- Bridle Joint

Let’s take a look more at each of these joinery:

1. Butt Joint

The butt joint is the most basic and straightforward wood joint. Woodworkers simply join two pieces of wood by placing their ends together to form a right angle. While easy to create, this joint lacks significant strength and is best suited for non-structural and lighter applications. Additional reinforcement through screws, nails, or glue is commonly employed to improve its durability.

2. Rabbet Joint

The rabbet joint involves cutting a groove or recess (rabbet) along the edge of one piece of wood, allowing the other piece to fit into it seamlessly. This joint provides a better gluing surface than the butt joint and offers increased strength and stability. Rabbet joints are widely used in cabinetmaking, drawer construction, and other applications where added strength is required.

3. Miter Joint

Miter joints are created by cutting two pieces of wood at an angle (usually 45 degrees) and joining them together to form a 90-degree corner. This joint creates a clean, elegant look and is often seen in picture frames, moldings, and decorative applications. However, miter joints can be weak on their own, and woodworkers may reinforce them with biscuits or splines to enhance their strength.

4. Lap Joint

Lap joints involve one piece of wood overlapping another to form a flush joint. There are various types of lap joints, such as the half-lap and cross-lap joints. They are relatively easy to make and provide moderate strength. Lap joints are commonly used in box constructions, cabinets, and frames.

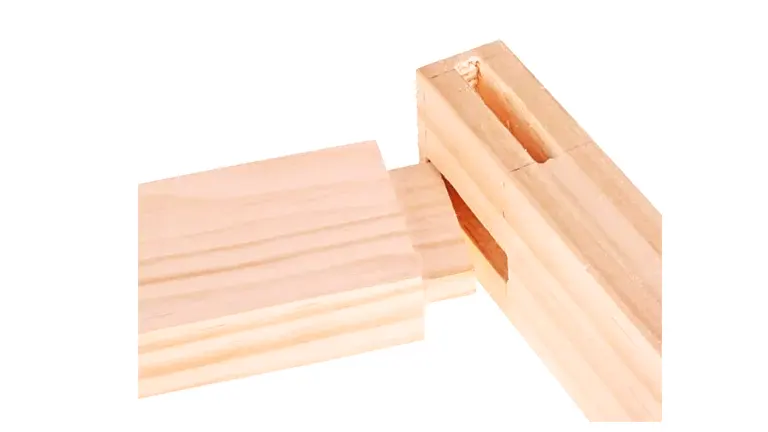

5. Dado Joint

A dado joint consists of cutting a slot or channel (dado) into one piece of wood to accommodate the end of another piece. Dado joints are often used to create shelves within bookcases or cabinets. This joint provides good strength and stability and can be further strengthened by gluing and screwing the pieces together.

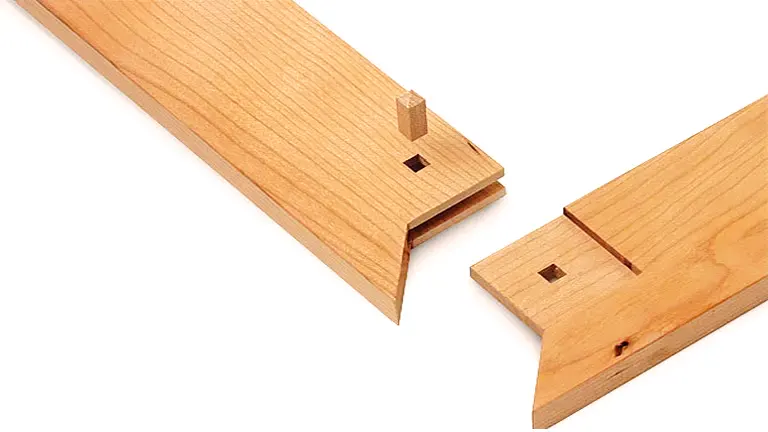

6. Spline Joint

The spline joint is a variation of the dado joint. It involves inserting a thin strip of wood (spline) into matching grooves on both pieces of wood. This joint helps prevent wood movement and is commonly used in panel constructions and picture frames.

7. Mortise and Tenon Joint

The mortise and tenon joint is one of the oldest and strongest woodworking joints. It involves cutting a square or rectangular hole (mortise) into one piece of wood and fitting a corresponding projecting tongue (tenon) on the other piece. This joint is widely used in furniture making and structural applications due to its exceptional strength and durability.

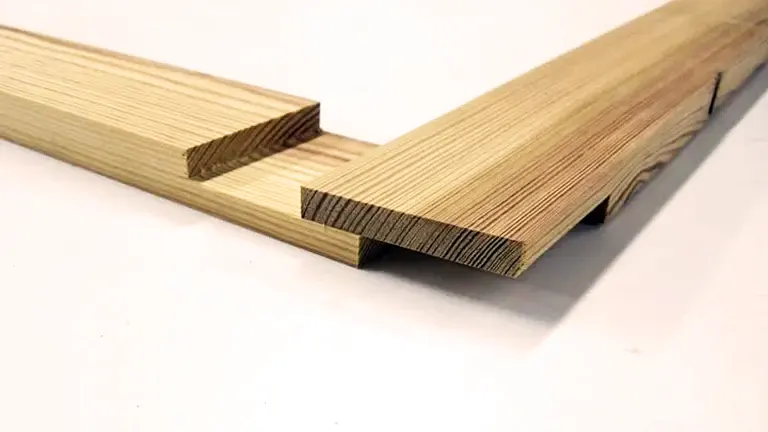

8. Tongue and Groove Joint

The tongue and groove joint consists of a protruding ridge (tongue) on one piece of wood that fits into a corresponding slot (groove) on another piece. This joint creates a strong and tight fit and is commonly used in flooring, paneling, and joinery.

9. Finger Joint

Also known as a box joint, the finger joint involves interlocking rectangular “fingers” cut into the ends of two pieces of wood. This joint provides a large gluing surface, making it strong and resistant to pulling forces. Finger joints are often used in box construction and drawer making.

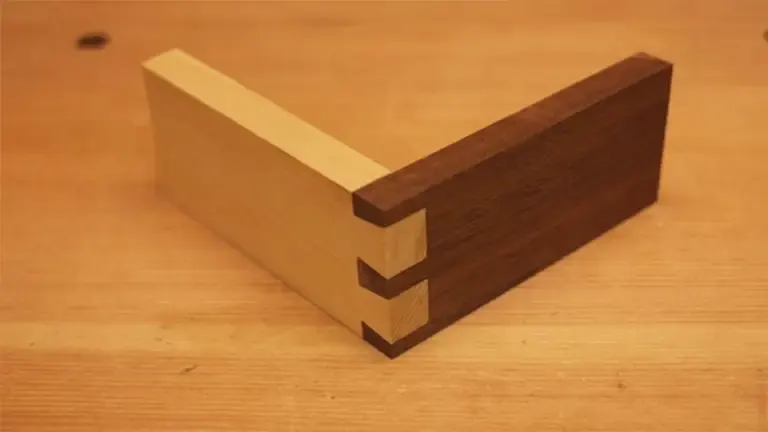

10. Dovetail Joint

The dovetail joint is a classic and aesthetically pleasing joint known for its exceptional strength and beauty. It involves interlocking trapezoidal-shaped pins and tails cut into the ends of two pieces of wood. Dovetail joints are commonly found in high-quality furniture, cabinets, and drawers, showcasing the skill and craftsmanship of the woodworker.

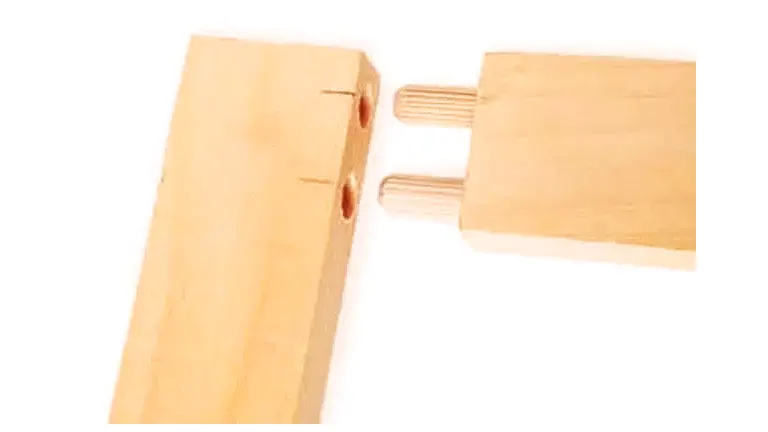

11. Dowel Joint

A dowel joint is a simple and effective method of joining two pieces of wood together. It involves drilling matching holes into the mating faces of the wood pieces and inserting cylindrical wooden rods (dowels) into the holes. The dowels act as alignment pins, ensuring a precise fit and proper alignment of the pieces during assembly. Glue is often applied to the dowels before inserting them, providing additional strength to the joint. Dowel joints are commonly used in furniture making, cabinet construction, and other woodworking projects where a strong and reliable connection is required without visible fasteners.

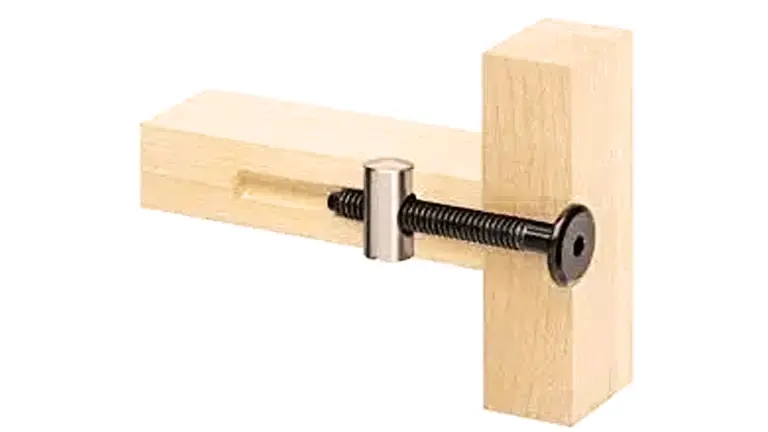

12. Cross Dowel Joint

The cross dowel joint is a variation of the dowel joint and is commonly used to join two pieces of wood at a 90-degree angle, forming a corner. It involves using a cylindrical rod (dowel) with a threaded hole drilled through its center. The mating face of one piece of wood is drilled with a clearance hole, and the other piece is drilled with a smaller pilot hole. The dowel is inserted through the clearance hole and into the pilot hole, and then a bolt is inserted and tightened into the threaded hole, creating a strong and secure connection. Cross dowel joints are often used in furniture assembly, especially in projects where disassembly and reassembly are required.

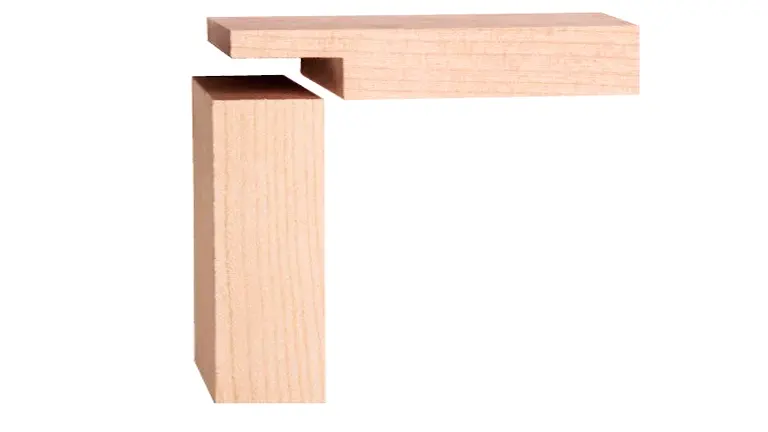

13. Bridle Joint

The bridle joint is a woodworking joint that connects two pieces of wood at a right angle. It resembles the mortise and tenon joint but has a key difference – both pieces have a through-mortise, and the tenon extends through both pieces, forming an open-ended “T” shape. The joint provides excellent strength and stability, making it suitable for load-bearing applications in frame constructions, railings, and furniture making. The exposed ends of the tenon add a decorative element to the joint, enhancing its overall aesthetics.

Conclusion

Woodworking’s art of joining wood is crucial for shaping project outcomes. Understanding various wood joints provides valuable insights into their strengths and limitations. Selecting the right joint impacts structural integrity and appearance. Woodworkers consider requirements, aesthetics, and use to make informed choices. Mastering diverse techniques enhances artistry and functionality. Each joint presents a unique challenge, rewarding artisans with a sense of accomplishment. Skillful application brings visions to life with beauty and stability. Exploring wood joints unlocks possibilities for enduring art and furniture. Knowledge of wood joints is the cornerstone of craftsmanship, binding passion and mastery in this timeless craft.

FAQs

- What is wood joinery, and why is it important in woodworking?

Wood joinery refers to the method of connecting two or more pieces of wood together to create a sturdy and durable structure. It is crucial in woodworking because it determines the strength, stability, and overall appearance of the finished piece. - What are some common types of wood joinery techniques used by woodworkers?

There are several common wood joinery techniques used in woodworking, including dovetail joints, mortise and tenon joints, finger joints, butt joints, and rabbet joints. Each method has its unique strengths and applications. - How do I choose the right wood joinery technique for my woodworking project?

Selecting the appropriate wood joinery technique depends on factors such as the type of project, the wood species being used, the desired aesthetics, and the level of woodworking experience. Researching and understanding each technique’s strengths and limitations will help in making an informed choice. - What tools are typically used for wood joinery?

The tools required for wood joinery can vary depending on the specific technique. Some common tools include saws (e.g., handsaw, dovetail saw), chisels, routers, drills, mallets, and clamps. Advanced woodworking projects may require specialized tools like a router table or a dovetail jig. - How can I improve my wood joinery skills?

Improving wood joinery skills takes practice and patience. Consider starting with simple projects and gradually progressing to more complex ones as you gain confidence. Seek out woodworking classes, online tutorials, or woodworking communities where you can learn from experienced woodworkers. Additionally, investing in high-quality tools and understanding wood properties will contribute to better joinery outcomes.

We value your input! Feel free to share your personal experiences and thoughts about the Woodcutter Camp Forestry Hatchet in the comments section. Your insights have the potential to assist fellow outdoor enthusiasts in making well-informed choices for their adventures!

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

That's very nice and I want to see many of this joints

Chet Sanata

March 20, 2024 1:57 pm