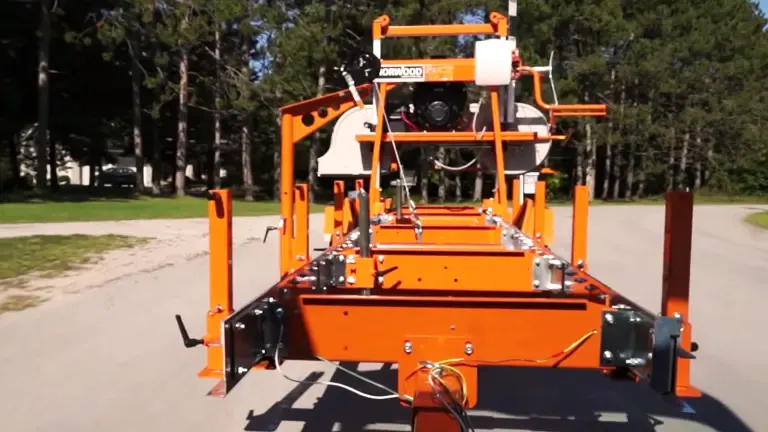

Norwood LumberMate LM30 Review

- July 26, 2023

- 0 comment

The LumberMate LM30 portable sawmill from Norwood Sawmills represents a monumental shift in the realm of woodworking. This machinery epitomizes a perfect blend of traditional craftsmanship and advanced technology, setting new standards for precision, efficiency, and versatility. Let’s delve deeper into the remarkable features that the LM30 offers.

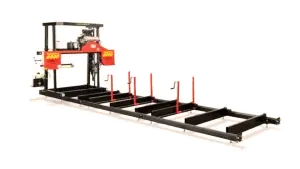

LumberMate LM30 Specifications

- Maximum log diameter: 30 inches

- Maximum board width: 12 inches

- Maximum board length: 10 feet (with optional track system)

- Weight: 150 pounds

- Frame material: Steel

- Sawmill type: Chainsaw

- Chainsaw requirements: 66cc or greater chainsaw with ripping chain

- Price: $5,880.00

Additional Features

- Adjustable blade depth

- Quick-release chainsaw mount

- Log rests and adjustable log dogs

- Track system (optional)

- Oiler (optional)

- Carrying case

- Sawyer-Assist Technology

- Rigid 4″ tubular port directs sawdust down toward the ground. Or use it to connect a chip-extractor and exhaust the sawdust outside your sawing shed.

- Dual fixed 1¼” blade guides are precision-machined, hardened, zinc-dichromate plated, and include sealed double ball bearings.

- Ten micro-adjust leveling feet for ground-level stationary sawing help ensure the mill stays stable for safe, accurate cuts.

Personal Experience

Ever since the LumberMate LM30 found its way into my life, my experience with woodworking has been nothing short of transformative. Setting up this sturdy, intuitively designed machine was a cinch. The real magic happened, though, when I put it to the test with a sizable oak log. The LM30 handled it effortlessly, and the lumber it produced was smooth, uniform, and ready for further processing. The band blade was a revelation, cutting through the tough oak like a hot knife through butter, with minimal sawdust to boot.

My favorite feature of the LM30 is, without a doubt, the auto-locking saw head. Adjusting the cut thickness has never been simpler, and the accuracy it delivers, regardless of whether I’m milling thin veneers or robust beams, is truly impressive. The adjustable blade guide provides extra control, ensuring every cut is smooth and precise. It’s these touches that make working with the LM30 not just efficient, but a real joy.

Now, let’s talk about the additional attachments that I opted for. The hydraulic log loading system has been a game-changer, saving my back from the strain of loading heavy logs. And the board offloading system? It’s a real time-saver that has made my milling process faster and more efficient. The added bonus is that the LM30’s portability and easy towing feature make it perfect for remote projects. It’s a dream come true for a woodworker like me.

Last but not least, I must mention the LM30’s safety features. The blade guards and ergonomically placed controls provide me with peace of mind when I’m working. As a professional woodworker, safety is paramount, and I’m relieved that the LM30 holds the same sentiment. All in all, the LumberMate LM30 has proved to be an extraordinary partner. It’s not just a tool, but an essential part of my woodworking journey that has brought both higher quality and an exciting edge to my business.

The Blade: The Unsung Hero

The blade used in the LM30 is a critical factor in its efficiency and precision. The LM30 uses a band blade, renowned for its sharpness and durability. This type of blade produces less sawdust than circular blades, enhancing the yield from each log. The blade guide is adjustable, giving the operator added control over the cuts, which results in smooth, clean lumber every time.

An optional debarker can be added to the LM30. This tool removes the bark from the log before it reaches the blade, increasing the blade’s life by protecting it from dirt and rocks that can dull it prematurely.

Handling & Transport

When considering a sawmill, one must not overlook the importance of its handling and transport capabilities. These features directly impact the ease and efficiency of the entire milling process, from log acquisition to the actual cutting. With the LumberMate LM30, handling and transport have been thoughtfully designed to enhance user convenience and productivity.

The LM30 is built for mobility. Unlike some stationary sawmills that require logs to be transported to the mill, the LM30 reverses this process. It can be easily towed by a standard vehicle, which means it can be brought directly to the logs. This feature is particularly beneficial when working with large, heavy logs that would otherwise require significant effort or specialized equipment to move. With the LM30, the mill comes to the logs, not the other way around, simplifying the logistics of log milling.

The LM30’s transport capabilities are further enhanced by the integration of a trailer system. This isn’t just any trailer system, though. It’s designed with a quick-connect/disconnect system that allows for a rapid and hassle-free setup and breakdown. Whether you’re moving the sawmill to a new location or getting ready to start milling, the system is designed to get you up and running in no time. This can significantly reduce idle time and increase overall productivity.

Moreover, the trailer system is designed with stability in mind. Whether in transport mode or when set up for milling, the LM30 remains stable, ensuring a safe and efficient operation. The robust construction of the LM30 and its trailer system also means it’s built to withstand the rigors of transport and frequent use.

Sawing Large Logs

One of the key features that sets the LumberMate LM30 apart from many other sawmills in the market is its exceptional capacity to handle large logs. While many sawmills may struggle with larger material, the LM30 is designed to accommodate logs up to 30 inches in diameter and up to 17 feet in length. This allows users to process substantial logs without the need for extra machinery or time-consuming splitting.

However, the LM30 doesn’t stop at the standard dimensions. Recognizing that woodworkers often encounter logs that exceed typical measurements, the LM30 provides the option to add log deck extensions. These extensions increase the mill’s length, enabling it to securely hold and process extra-large logs. This flexibility means that no log is too long for the LM30, making it a go-to solution for projects of all sizes.

But what about the challenge of milling logs that aren’t uniformly cylindrical, or that have a taper? The LM30 has got that covered as well. The sawmill can be equipped with optional manual or hydraulic toe boards. These devices allow the operator to adjust the position of the log on the mill to compensate for taper. By raising the lower end of the log to align with the saw blade, the toe boards ensure consistent board thickness throughout the length of the log. This clever feature eliminates the guesswork and inconsistency often associated with milling tapered logs, providing precise and uniform cuts every time.

Safety Considerations

The LumberMate LM30 prioritizes safety as much as efficiency and adaptability. It incorporates thoughtful design features that aim to reduce risk and enhance operator safety during operation.

A fundamental safety feature of the LM30 is the inclusion of blade guards. These guards act as a protective barrier between the operator and the saw blade, serving to prevent accidental contact. They play a critical role in reducing the risk of injuries that could occur due to slips or mishaps while operating the sawmill. These blade guards are not just a mere add-on; they are integral to the machine’s design, reinforcing the manufacturer’s commitment to safe operation.

Complementing the blade guards is the strategic placement of the LM30’s controls. The designers of the LM30 understood that maintaining a safe distance from the cutting area during operation is key to safety. Hence, the controls have been ergonomically placed to ensure the operator can fully control the machine without needing to be near the cutting area. This design not only enhances safety but also contributes to the operator’s comfort, which is crucial during long hours of operation.

Safety on the LM30 isn’t just about physical design elements; it extends to the machine’s operation as well. For example, the hydraulic log loading system and the board offloading system minimize manual handling of heavy logs and boards, thereby reducing the risk of strain injuries.

Customizability: Beyond the Basics

One of the LumberMate LM30’s distinguishing features is its exceptional customizability. This sawmill doesn’t merely come as a one-size-fits-all package. Instead, it offers a variety of optional attachments, providing the flexibility to tailor the machine according to individual preferences and requirements.

Perhaps one of the most notable attachments is the hydraulic log loading system. Traditionally, loading logs onto a sawmill can be a strenuous process, especially when dealing with larger logs. However, with the hydraulic log loading system, this once laborious task becomes effortless. This feature simplifies the process, saves time, and reduces the risk of potential injury, making it a popular choice among users.

Another valuable add-on is the board offloading system. Once your logs are milled into boards, the offloading system takes over, moving the cut lumber away from the mill. This system not only speeds up the milling process but also keeps your workspace organized and efficient, allowing you to focus on what you do best – milling.

For those dealing with larger logs, the LM30 also offers optional log deck extensions. These extensions allow the LM30 to handle logs of greater lengths than its standard capacity, making it a versatile tool for any size of project.

In essence, the LumberMate LM30 provides an avenue for a seamless transition from a manual mill to a more sophisticated, automated operation. The optional attachments augment the sawmill’s capabilities, transforming it into a more productive and efficient machine.

Conclusion

The LumberMate LM30 is a game-changer in the field of portable sawmills. Its emphasis on power, precision, and safety, combined with its potential for customization, makes it an invaluable tool for a diverse range of woodworking needs. Above all, the LM30 is a testament to how the harmonious blend of traditional craftsmanship and innovative technology can lead to exceptional outcomes.

Frequently Asked Questions

- What type of logs can the LumberMate LM30 handle?

The LM30 can handle logs up to 30 inches in diameter and up to 17 feet in length. For larger logs, optional log deck extensions can be added. - What kind of cuts can I make with the LumberMate LM30? Thanks to the auto-locking sawhead, the LM30 can make accurate cuts of varying thickness, from thin veneer to robust beams.

- Is the LumberMate LM30 portable?

Yes, the LM30 is designed for easy towing, allowing you to bring it directly to the logs. It can be towed using a standard vehicle. - Can the LumberMate LM30 be customized? Absolutely! The LM30 has been designed with customization in mind. Various optional attachments can be added, such as a hydraulic log loading system, a board offloading system, and more.

- How safe is the LumberMate LM30 to operate?

Safety is a key consideration in the LM30’s design. It comes with blade guards to protect the operator from the blade and ergonomically placed controls to keep the operator away from the cutting area. - What kind of blade does the LumberMate LM30 use?

The LM30 uses a band blade known for its sharpness and durability. This type of blade produces less sawdust than circular blades, enhancing the yield from each log. - Is the LumberMate LM30 suitable for commercial use?

Yes, the LM30 is suitable for both personal and commercial use. Its versatility, combined with the option to add automated features, makes it an excellent choice for custom woodworking businesses.

We hope you found this deep dive into the LumberMate LM30 interesting and helpful. Are you a current user of the LM30, or perhaps you’re considering adding one to your woodworking arsenal? We’d love to hear from you! Share your thoughts, experiences, or any questions you might have about the LumberMate LM30 in the comments below. Let’s keep the conversation going!

Leave your comment