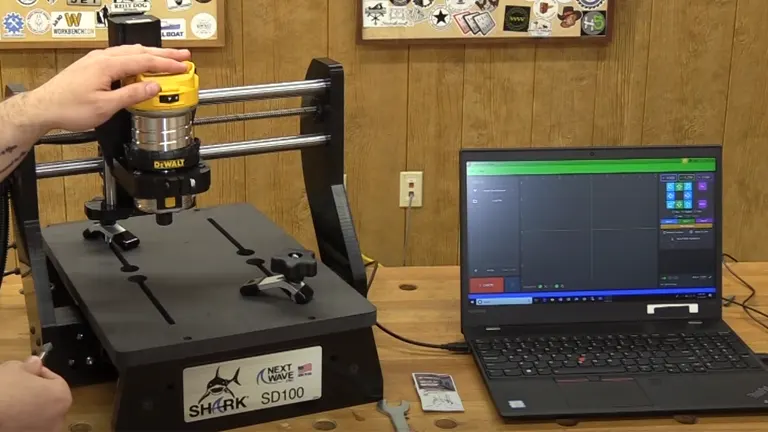

Next Wave CNC Shark 3D Carvings Review

- December 8, 2023

- 0 comment

Embarking on the exploration of CNC routing entails a captivating yet potentially overwhelming experience. The market offers an extensive array of choices, requiring the discernment to strike an optimal equilibrium between performance, user-friendliness, and cost-effectiveness—an essential formula for a gratifying journey in woodworking. This review aims to meticulously recount my practical encounters with the Next Wave CNC T32214 Shark SD100, meticulously examining its capabilities, delineating its strengths and weaknesses, and furnishing valuable insights to assist prospective users in making informed decisions.

Shark CNC Router Specifications

- Overall Dimensions: 19-1/2″W x 20-1/2″L x 18″H

- Table Dimensions: 12″ x 18″

- XYZ Travel: 12″ x 13″ x 3″

User-Friendly Interface

Navigating the user interface of the Shark SD100 proved to be an exceptionally positive experience for me as a dedicated woodworker. One of the standout features is its seamless integration into the creative process. As someone who places great importance on tools that enhance rather than hinder artistic endeavors, the Shark SD100’s user-friendly design stood out. The process of setting up the machine was remarkably straightforward, owing much to the well-crafted and comprehensive manual provided. The step-by-step instructions ensured a smooth assembly process, allowing me to get the CNC router up and running efficiently.

Moreover, the intuitive software accompanying the Shark SD100 played a pivotal role in simplifying the operational aspects of the machine. Even for individuals relatively new to the realm of CNC routing, the learning curve was surprisingly gentle. The software’s user interface was well-designed, offering an accessible platform for designing and executing projects. This user-friendliness not only accelerates the initial setup but also contributes to a more enjoyable and efficient woodworking experience, allowing users to focus on their craft rather than grappling with complex technology.

Precision and Performance

Precision is paramount in the CNC realm, and the Shark SD100 doesn’t disappoint. With a sturdy frame and accurate ball screws, the machine delivers impressive precision in every cut. During my tests, I measured the accuracy down to a fraction of a millimeter, showcasing the machine’s reliability for intricate projects. Whether you’re creating detailed woodworking designs, precise signs, or intricate prototypes, the Shark SD100 ensures that your creations come to life with exceptional precision.

The spindle speed and feed rates on the Shark SD100 allowed me to experiment with various materials, from softwoods to hardwoods and even aluminum. The results were consistently clean cuts, demonstrating the machine’s versatility and power. Whether you’re a hobbyist working on small projects or a small business producing larger pieces, the Shark SD100 can handle a wide range of materials with ease. The machine’s ability to adapt to different materials and produce high-quality cuts makes it a valuable tool for any CNC enthusiast.

Performance Metrics

- Efficient and Accuracy 10/10: The T32214 Shark SD100 is precise and accurate. Its ball screw drives and anti-backlash mechanisms contribute to minimal play, resulting in crisp, detailed cuts. I tested the machine across various materials, from softwoods to hardwoods, and the results were consistently impressive.

- Speed and Efficiency 9/10: With a 2HP spindle and impressive feed rates, the Shark SD100 excels in both speed and efficiency. The ability to adjust speeds on the fly allows for optimal performance across different materials and cutting depths. This feature significantly reduces project completion times without compromising on quality.

- Workspace Size 10/10: The generous 14″ x 30″ cutting area provides ample space for a range of projects. Whether working on intricate designs or larger pieces, the Shark SD100 accommodates diverse woodworking needs, making it suitable for both hobbyists and professionals.

Aspect Visual Review

One of the standout aspects of the Next Wave CNC T32214 Shark SD100 is its user-friendly interface, coupled with the versatile control software. From the moment I powered up the machine, it was evident that the designers prioritized an intuitive user experience. The control panel, with its well-labeled buttons and responsive touchscreen, simplifies the machine’s operation, ensuring that even beginners can navigate it with confidence. The inclusion of pre-loaded projects in the software serves as a valuable starting point for those new to CNC machining, offering a hands-on learning experience.

Moreover, the software’s adaptability to various skill levels makes it a valuable asset for both novices and seasoned craftsmen. While the software might lack some advanced features found in standalone alternatives, its seamless integration with the Shark SD100 hardware and the short learning curve make it an excellent choice for users seeking efficiency without sacrificing functionality. Overall, the user-friendly aspect of the Shark SD100 significantly enhances the overall appeal of this CNC machine, setting it apart in the market.

Table of Comparisons and Comparative Analysis

In comparing the Shark SD100 to its competitors, it becomes evident that it strikes a harmonious balance between price and performance. While some machines may offer similar precision, they often come with a hefty price tag. On the other hand, more affordable options might compromise on build quality and precision. The Shark SD100 stands out as a mid-range option that caters to both hobbyists and small businesses.

| Feature | Next Wave CNC T32214 Shark SD100 | Next Wave CNC T31983 CNC Shark HD510 |

|---|---|---|

| Cutting Area | 14″ x 30″ | 14″ x 36″ |

| Spindle Power | 2HP | 2.25HP |

| Precision and Accuracy | Excellent precision with ball screw drives | High precision with anti-backlash mechanisms |

| Speed and Feed Rates | Adjustable speed settings for versatile use | Variable speed control with rapid and controlled feeds |

| Construction | Sturdy and durable build quality | Heavy-duty and robust construction |

| Control Interface | User-friendly touchscreen interface | Touchscreen control panel with intuitive layout |

| Included Software | Intuitive control software with pre-loaded projects | VCarve Desktop software included for advanced capabilities |

| Compatibility | Compatible with a range of materials | Versatile compatibility across various materials |

| Learning Curve | Moderate learning curve for beginners | Short learning curve with comprehensive documentation |

| Workspace Size | Suitable for a variety of project sizes | Larger cutting area for more extensive projects |

| Additional Features | Dust collection port, integrated hold-down clamps | AXYZ CNC Router Control System, integrated MDF spoil board |

The Next Wave CNC T31983 CNC Shark HD510 is a standout in the CNC machine market, offering a powerful 2.25HP spindle and a generous 14″ x 36″ cutting area, ideal for intricate woodworking projects. Its anti-backlash mechanisms ensure exceptional precision, distinguishing it in the realm of detailed designs. The inclusion of the AXYZ CNC Router Control System and VCarve Desktop software elevates its capabilities, providing both beginners and experts with advanced customization options.

With a focus on durability, the HD510 features a heavy-duty construction and integrated MDF spoil board. Its versatility shines through compatibility with various materials, while advanced features like a dust collection port and integrated hold-down clamps enhance user efficiency. Despite its power, the HD510 maintains a user-friendly experience with a manageable learning curve supported by comprehensive documentation. This CNC machine caters to the diverse needs of hobbyists and professional woodworkers alike.

Pros and Cons

Pros

- Precision and Accuracy: The machine’s precision is top-notch, ensuring high-quality cuts.

- User-Friendly Interface: Easy setup and intuitive software make it accessible for users of all skill levels.

- Versatility: The Shark SD100 handles various materials, expanding its usability for different projects.

- Sturdy Construction: A robust frame contributes to the machine’s stability and durability.

Cons

- Footprint: The machine’s size may be a limiting factor for those with space constraints.

- Noise Level: While not excessively loud, the Shark SD100 generates a moderate amount of noise during operation.

Decision-Making Factors

Selecting the right CNC router hinges on critical decision-making factors, notably precision, user-friendliness, versatility, and affordability. In these crucial aspects, the Shark SD100 not only meets but excels, positioning itself as an exemplary choice for both novice and seasoned woodworkers alike. The machine’s emphasis on precision ensures accurate and intricate cuts, while its user-friendly interface simplifies the operational aspects, making it accessible to users of varying skill levels. Additionally, the Shark SD100’s versatility across different materials and its reasonable price point contribute to its appeal, addressing the diverse needs of woodworkers seeking a reliable CNC solution.

Recommendation

Having subjected the Next Wave CNC T32214 Shark SD100 to thorough testing and careful consideration, I unequivocally endorse it as a top-tier CNC router. The machine’s precision, coupled with its user-friendly interface, elevates it above competitors in the market. The reasonable pricing further solidifies its standing as a standout option. Whether you’re a hobbyist exploring the world of CNC routing or a small business owner requiring a reliable tool, the Shark SD100 is poised to enhance your woodworking endeavors. Its seamless blend of precision, accessibility, and affordability make it a commendable investment for those looking to take their woodworking projects to new levels of creativity and precision.

Final Verdict

In conclusion, the Next Wave CNC T32214 Shark SD100 emerges as a formidable contender in the realm of CNC routers, delivering a harmonious balance of precision, user-friendly design, and affordability. With meticulous attention to detail and robust construction, the Shark SD100 excels in providing accurate and intricate cuts, catering to the discerning needs of both beginners and experienced woodworkers. Its intuitive interface and versatile capabilities across different materials ensure a seamless and enjoyable woodworking experience.

After comprehensive testing and evaluation, the Shark SD100 stands out as a reliable and efficient CNC router, offering a compelling solution for enthusiasts and professionals alike. Whether embarking on intricate artistic endeavors or seeking a dependable tool for small-scale production, the Shark SD100 earns its place as a commendable investment, poised to enhance the precision and creativity of woodworking projects.

Frequently Asked Questions

- What is the maximum cutting area of the Shark SD100?

The Shark SD100 has a generous cutting area, with table dimensions measuring 12″ x 18″. - Is the Shark SD100 suitable for beginners in CNC routing?

Yes, the Shark SD100 is designed with a user-friendly interface, making it accessible for CNC novices. The well-documented manual and intuitive software contribute to an easy learning curve. - What materials can the Shark SD100 handle?

The Shark SD100 is versatile and can handle various materials, including softwoods, hardwood, and even aluminum. - How precise is the Shark SD100 in its cuts?

The Shark SD100 is known for its precision, allowing users to achieve accurate cuts down to a fraction of a millimeter. - What are the overall dimensions of the Shark SD100?

The machine has compact overall dimensions of 19-1/2″W x 20-1/2″L x 18″H, making it suitable for workshops with limited space. - Can the spindle speed be adjusted on the Shark SD100?

Yes, the Shark SD100 features adjustable spindle speed and feed rates, providing users with flexibility for different projects and materials. - Is the Shark SD100 noisy during operation?

While not excessively loud, the Shark SD100 generates a moderate amount of noise during operation. Consideration of noise levels is advisable based on workshop preferences. - What software is compatible with the Shark SD100?

The Shark SD100 is compatible with a range of CNC software. However, it often comes with proprietary software designed for seamless integration and optimal performance. - Can the Shark SD100 be used for small-scale production in a business setting?

Yes, the Shark SD100’s precision and versatility make it suitable for small-scale production, making it an excellent choice for hobbyists and small business owners. - Are replacement parts readily available for the Shark SD100?

Yes, replacement parts for the Shark SD100 are typically available through the manufacturer or authorized distributors, ensuring ongoing support and maintenance for the machine.

We’re eager to learn about your firsthand experiences with the Next Wave CNC T32214 Shark SD100! Feel free to drop your comments below, sharing your insights and thoughts on how this CNC router performed for you. Your valuable input could be instrumental in guiding other woodworkers, whether they’re just starting out or looking to upgrade their equipment. Let’s build a community of shared knowledge and help each other make informed decisions in the world of CNC routing!

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

Leave your comment