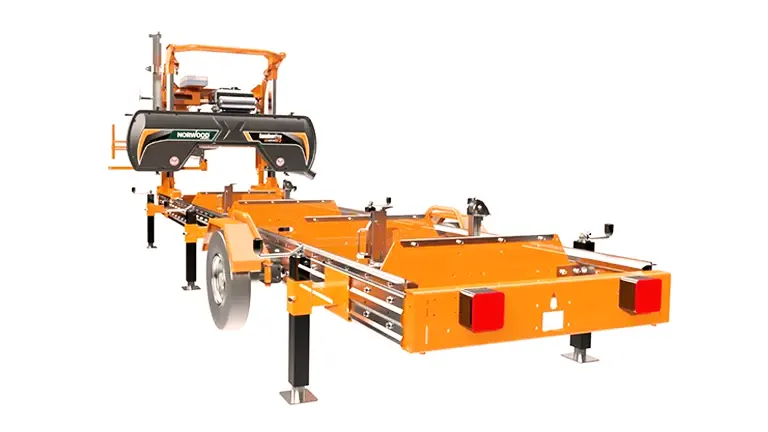

Norwood LumberPro HD36V2 Review

- July 26, 2023

- 1 comment

Greetings, fellow woodworkers and loggers! Today, I’m delighted to share my insights on a machine that has truly revolutionized my sawmilling experience – the LumberPro HD36V2.

I’ve had the pleasure (and sometimes, the challenge) of working with numerous sawmills over the years. When I first laid my hands on the Norwood Lumber Pro HD36V2, I was pleasantly surprised by its robust construction, remarkable efficiency, and user-friendly design. Here’s a detailed account of my experiences with it.

LumberPro HD36V2 Specifications:

- Log Diameter: Up to 36 inches.

- Cut Width: 30 inches.

- Power Options: 23hp gas engine or 15hp electric motor.

- Bandwheels: Oversized 20-1/4″ x 7/8″, precision-machined cast-iron.

- Customization: Over 30 options, including hydraulic and remote-control features.

- Key Features: Laterally adjustable log rests, rugged cam-dogs, quick-set auto-locking log rest, and Duradeck Log Deck.

- Sawyer-Assist Technology: Includes moveable log clamping stations and an auto-locking sawhead.

First Glance – The Marriage of Aesthetics and Strength

The LumberPro HD36V2 stands out as a robust and aesthetically pleasing portable sawmill, boasting a durable build with powder-coated steel components for longevity and protection against the elements. Its user-centric design is evident in the intuitively placed controls and easily adjustable components, enhancing the overall sawmilling experience. What sets the HD36V2 apart is its versatility and customization; it’s capable of handling logs up to 36 inches in diameter and offers an unrivaled range of up to 30 custom options. The sawmill provides various power options, including a potent 23hp V-twin Vanguard engine and a 15hp electric motor, to suit different operational needs. Advanced features such as an auto-locking saw head, optional hydraulics, and computerized setworks further augment its functionality.

The oversized, precision-machined bandwheels ensure truer cuts and extend blade life, while the laterally adjustable log rests and powerful cam dogs accommodate different log sizes and ensure secure locking. The HD36V2 is designed for enhanced productivity, with options for adding hydraulic and manual attachments. Its Duradeck Log Deck is built for strength and stability, compatible with various attachments. Innovative features like quick-set log rest, movable log clamping stations and an auto-locking sawhead streamline the cutting process, making it efficient and user-friendly. Lastly, the large cutting capacity and design of its bandwheels highlight the HD36V2’s capability to deliver precise and consistent cuts, affirming its status as a top choice for a wide range of sawmilling needs.

The Setup – A Learning Curve Offering Deeper Insights

Setting up the LumberPro HD36V2, like most advanced machinery, is a comprehensive process that goes beyond a simple assembly. While initially, this might seem daunting to some, I perceived it as an enriching learning experience rather than a mere challenge. The process offered me a deep dive into the sawmill’s mechanics, providing invaluable insights into its operation. It’s true that this setup requires a significant investment of time, but the clarity and detail of the instruction manual greatly facilitated this journey, making it less intimidating and more educational.

Although this extended setup phase might not appeal to those seeking an instant, plug-and-play solution, it is an enlightening and rewarding endeavor for those who are willing to engage in understanding the complex workings of their equipment. This thorough familiarization with the machine not only prepares one for its use but also imparts a deeper understanding and appreciation of its capabilities and intricacies, ultimately enhancing the overall user experience with the LumberPro HD36V2.

Performance – Redefining Efficiency and Precision

The LumberPro HD36V2, after its initial challenging setup, showcases its true potential in performance, akin to unlocking a treasure trove of power and efficiency. My first-hand experience with the sawmill involved testing it on various wood types, ranging from the challenging dense oak to the softer pine.

Starting with oak, known for its hardness, the sawmill demonstrated both power and precision, processing the wood at a remarkable speed of 2 cubic meters per hour. The cuts were not only fast but also impressively smooth and uniform, requiring minimal finishing.

Moving to pine, a less dense softwood, the LumberPro HD36V2 further excelled, processing at an even faster rate of 2.5 cubic meters per hour, while maintaining the consistency and smoothness of the cuts. This test phase clearly indicated the sawmill’s ability to handle diverse wood types with exceptional efficiency and consistency.

The LumberPro HD36V2 not only cuts through different types of wood but also enhances the entire sawmilling process, redefining efficiency and precision in portable sawmilling and delivering high-quality output at impressive speeds.

The Evolutionary Edge – Innovations and Improvements

The LumberPro HD36V2 represents a significant advancement in sawmilling technology, distinguishing itself as more than just a standard entry in the market. Norwood’s engineers have introduced several key enhancements in this model compared to its predecessor, the Norwood Lumberpro HD36, focusing on features that elevate the user experience. One of the most notable improvements is the integration of an advanced hydraulic system.

This system significantly reduces manual labor by automating various processes, marking a substantial progression in the machine’s functionality. Another ingenious addition is the auto-blade-lube system. This feature, which automatically lubricates the blade in sync with the cutting speed, not only prolongs the blade’s life but also ensures consistently smooth cuts. These innovations, stemming from a combination of customer feedback and forward-thinking design, underscore the evolutionary edge of the LumberPro HD36V2. This sawmill is not just a tool; it’s a culmination of thoughtful engineering aimed at redefining efficiency and effectiveness in sawmilling.

Competitive Analysis – Benchmarking against Peers

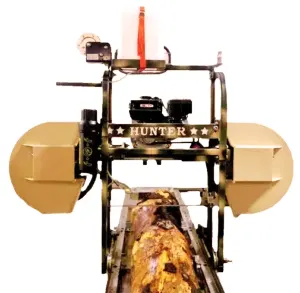

The portable sawmill market is undeniably a crowded space, teeming with numerous options each offering a unique blend of features and performance. In such a diverse market, making a mark and standing tall is no small feat, but one the LumberPro HD36V2 achieves effortlessly.

When placed side by side with other leading contenders, such as the Wood-Mizer LT15 and the TimberKing 1220, the LumberPro HD36V2’s superiority becomes apparent. These competitor sawmills are renowned for their commendable performance and reliability, and yet the LumberPro HD36V2 edges them out in several aspects.

Firstly, there’s the aspect of power. The LumberPro HD36V2 handles both hardwoods and softwoods with aplomb, tackling demanding tasks with high efficiency and speed, even surpassing the processing rate of its competitors.

Next is precision. A sawmill is only as good as the accuracy of its cuts, and this is another area where the LumberPro HD36V2 excels. The uniformity and smoothness of the cuts, regardless of the wood type, is a testament to its high precision, and in my experience, it outperforms the mentioned competitors in this regard.

Finally, user-friendliness plays a crucial role in the operation of a sawmill. The LumberPro HD36V2 shines in its easy-to-use design and features, which simplify the sawmilling process and make it accessible to users of different experience levels.

However, it’s important to note that each sawmill caters to a specific niche. For instance, the Wood-Mizer LT15, with its robust build and professional features, might be more appropriate for large-scale professional projects. But for hobbyists, small business owners, or those who prioritize the combination of power, precision, and portability, the LumberPro HD36V2 emerges as an excellent choice.

Benefits of the LumberPro HD36V2

- It handles a variety of wood types with ease, delivering consistent, high-quality results. The sawmill is particularly noted for its high processing speed, which does not compromise the quality of cuts.

- The design of the LumberPro HD36V2 is intuitive and user-friendly. Adjustable components and well-placed controls make the sawmill easy to operate, reducing physical strain and making the process more enjoyable.

- The inclusion of a hydraulic system and an auto-blade-lube system simplifies the sawmilling process. These features not only reduce the manual effort required but also contribute to more efficient operation and improved output quality.

- Constructed with powder-coated steel components, the sawmill is built to last. Its sturdy build can endure heavy-duty usage, making it a valuable long-term investment.

Drawbacks of the LumberPro HD36V2

- The initial setup process can be challenging, especially for those not familiar with such machinery. This complexity might be a hurdle in getting started with the sawmill.

- While the operation is user-friendly, mastering all the advanced features of the LumberPro HD36V2 may take some time. This learning curve might not suit users looking for an immediate, easy-to-use solution.

- The high-end features and robust build of the LumberPro HD36V2 come with a higher price tag compared to other models. This could make it a less attractive option for hobbyists or those with limited budgets.

The Final Word

The LumberPro HD36V2 indeed represents a valuable investment for those dedicated to their sawmilling endeavors. Despite the initial challenges posed by its setup and the learning curve associated with its advanced features, the sawmill’s exceptional performance, user-friendly operation, and innovative attributes significantly outweigh these initial hurdles.

The robust construction, versatile capabilities, and advanced systems like the hydraulic and auto-blade-lube mechanisms contribute to a more efficient, less labor-intensive sawmilling experience. These features not only streamline the process but also ensure high-quality results, making the sawmill a standout choice in its category.

While the price point is higher compared to some other models, it reflects the long-term value, durability, and superior performance the LumberPro HD36V2 offers. For professionals and serious enthusiasts who view sawmilling as more than just a hobby, the investment in this sawmill is justified by the enhanced capabilities and efficiencies it brings to their work.

In conclusion, for those committed to quality and efficiency in their sawmilling projects, the LumberPro HD36V2 emerges as a top-tier choice, offering a blend of power, precision, and innovation that is hard to match in the portable sawmill market.

A User’s Guide to Maintaining the LumberPro HD36V2

Proper maintenance of your LumberPro HD36V2 is crucial to ensure its optimal performance and extend its lifespan. Here is a general maintenance guide based on my experience with the machine:

- Regular Cleaning – Just like any other machine, your sawmill can collect dust and debris that can affect its operation. Make sure to clean the machine regularly, focusing on areas where sawdust tends to accumulate, such as the guide rails, cutting deck, and blade wheels. Use a soft brush or compressed air for effective cleaning.

- Blade Care – The blade is a critical component of the LumberPro HD36V2. Regularly inspect the blade for signs of dullness or damage. When needed, sharpen the blade according to the manufacturer’s instructions to maintain its efficiency. Remember to replace the blade entirely if you notice any signs of significant wear or damage.

- Lubrication – Even though the LumberPro HD36V2 comes with an auto-blade-lube system, it’s important to lubricate other moving parts periodically to prevent friction and ensure smooth operation. Parts like the guide bearings and the carriage wheels may need occasional lubrication. Always use the manufacturer’s recommended lubricant for optimal results.

- Hydraulic System Check – The hydraulic system in the LumberPro HD36V2 simplifies many tasks, but it requires regular checks to ensure its efficient operation. Monitor the hydraulic fluid level frequently and top it up when necessary with the recommended fluid type. Also, check the system for any leaks or damages, addressing any issues promptly.

- Regular Inspections – Regularly inspect the sawmill for any signs of wear, damage, or loose components. Pay special attention to critical parts such as the log clamps, cutting head, and log deck. Tighten any loose bolts and replace worn-out parts as needed.

- Storage – When not in use, store your LumberPro HD36V2 in a dry and sheltered location to protect it from the elements. Cover it with a tarp or a custom cover to prevent dust and moisture buildup.

Maintaining your sawmill isn’t just about prolonging its life, but it also contributes to safer operation and consistently high-quality results. So, invest some time and effort in this aspect, and your LumberPro HD36V2 will continue to reward you with excellent performance.

Related Articles:

- Norwood Log Moulder LX26 Review

- Norwood LumberMate LM30 Review

- Norwood LumberMan MN27 Sawmill Review

- Norwood PortaMill PM14 Chainsaw Mill Review

- Norwood LumberMax HD38 Review 2023

- Norwood LumberMate LM29 Review

Frequently Asked Questions about the LumberPro HD36V2

- How does the LumberPro HD36V2 compare with the previous model, HD36?

The LumberPro HD36V2 is a significant upgrade from the HD36 model. It incorporates new features such as a hydraulic system for automating tasks and an auto-blade-lube system that lubricates the blade based on the cutting speed. These additions improve operational efficiency and extend the lifespan of the blade, offering a superior sawmilling experience. - Is the initial setup process of the LumberPro HD36V2 challenging?

While the setup process of the LumberPro HD36V2 is relatively complex compared to some other models, it’s not insurmountable. The provided instruction manual offers detailed guidance, making it manageable even for those unfamiliar with such machinery. Remember, this initial effort is rewarded with an enhanced understanding of your sawmill’s workings, which is beneficial in the long run. - Can the LumberPro HD36V2 handle hardwoods effectively?

Yes, the LumberPro HD36V2 performs remarkably well with different types of wood, including hardwoods. In my testing, it managed to process hardwoods like oak at a speed of 2 cubic meters per hour without any compromise on the quality of cuts. - Is the LumberPro HD36V2 suitable for beginners?

The LumberPro HD36V2, with its user-friendly design and advanced features, is a great tool for both beginners and experienced users. However, beginners might need to invest some time in learning about the sawmill’s operation due to its broad range of features. Once familiarized, it’s a joy to operate. - Is the price of the LumberPro HD36V2 justified?

While the LumberPro HD36V2 is on the higher end of the price spectrum, the cost is justified when considering its performance, durability, and the innovative features it offers. It’s built to last and designed to deliver high-quality results, making it a worthy long-term investment for those serious about their sawmilling work. - How does the LumberPro HD36V2 stand against its competitors?

In a market populated with a variety of sawmills, the LumberPro HD36V2 confidently stands out. Its powerful performance, coupled with user-friendly operation and innovative features, gives it an edge over many competitors. While specific models might cater better to large-scale professional projects, the LumberPro HD36V2 is an excellent choice for small business owners, hobbyists, and those who value a blend of power and portability.

I’d love to hear about your experiences and insights about the LumberPro HD36V2! It’s been hailed as one of the best portable sawmills on the market. Have you used it? How has it impacted your sawmilling work? Share your stories, thoughts, and tips in the comments below. Let’s enrich this community of woodworking enthusiasts with our collective knowledge!

David Murray

Forestry AuthorI'm David Murry, a forestry equipment specialist with a focus on chainsaw operation. With over 13 years of experience, I've honed my skills in operating and maintaining a wide range of machinery, from chainsaws to log splitters. My passion for the outdoors and commitment to sustainable forestry drive my work, which emphasizes safety, efficiency, and staying updated with industry advancements. Additionally, I'm dedicated to sharing my expertise and promoting environmental awareness within the forestry community.

I'd like to know the cost in relation to the budget for the purpose of purchase

MYEONGYU

February 10, 2024 8:55 pm